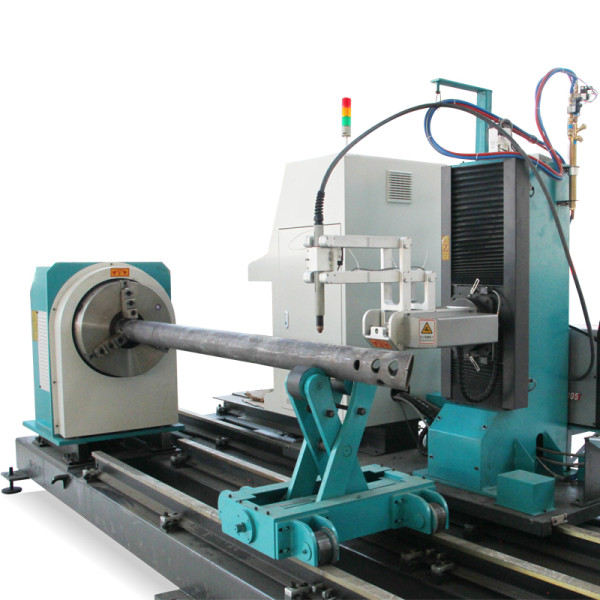

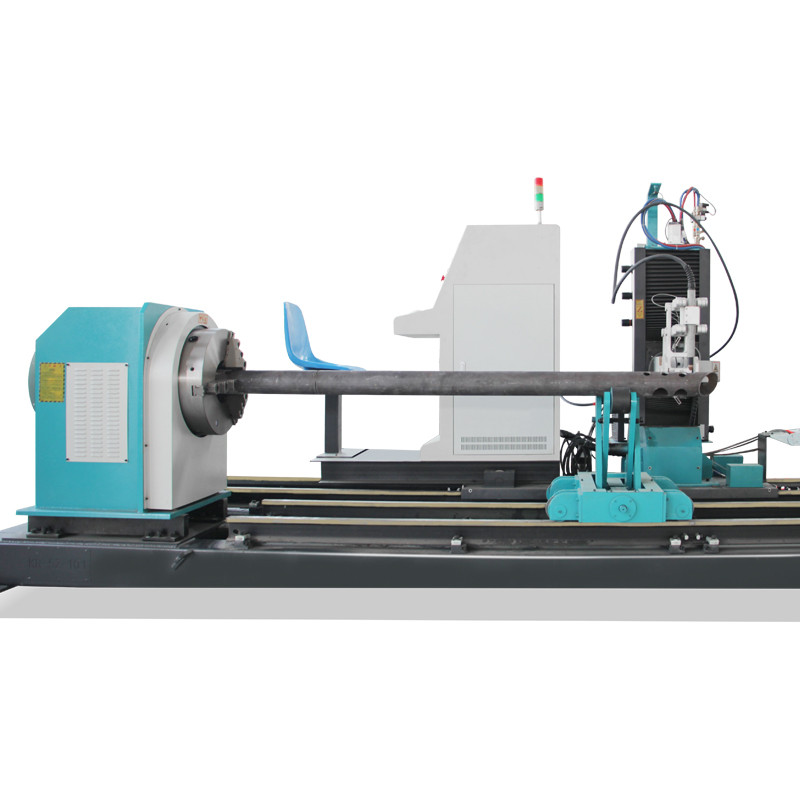

5 Axis Pipe CNC Plasma Cutting Machine

- Share

- Issue Time

- Oct 30,2023

Summary

5 Axis Pipe CNC Plasma Cutting Machine Feature and Technical Parameter.

Machine Feature

lIt can cut and bevel round pipe profiles with high degree of automation and cutting quality.

lIt has the characteristics of optimization material,3D simulation operation,node expansion,ultra long pipe partition, and other management functions.

lIt Support Tekla, 3D3S, CAD, SolidWorks with high compatibility, directly generate G code.

lIt can cut carbon steel, stainless steel,aluminium and ect.

lIt is widely used in pressure vessels, pipe processing,shipbuilding, steel structure, marine offshore engineering, oil pipeline,petrochemical and other industries.

Technical Parameter

NO. | Item | Parameters |

1 | Round pipe diameter | 60-630mm 60-800mm |

2 | Cutting length | 6000m/9000m/12000m or customized |

3 | Cutting mode | Flame/Plasma |

4 | Control system | Advantech IPC with YOMI PIPE |

5 | Driving system | Japanese Panasonic servo motors |

6 | Plasma cutting thickness | It is depended by plasma power source |

7 | Flame cutting thickness | Vertical cutting 6~60mm Bevel cutting 6-40mm |

8 | Plasma bevel angle | Plasma cutting ±45° |

9 | Flame bevel angle | Flame hole cutting±55° flame end cutting±60° |

10 | Required workpiece ellipticity | ≤1% |

11 | Cutting speed | 10~2000mm/min |

12 | Moving speed | 10~6000 mm/min |

13 | Cutting length accuracy | ±1.5mm |

14 | Maximum loading weight | 5000Kgs |