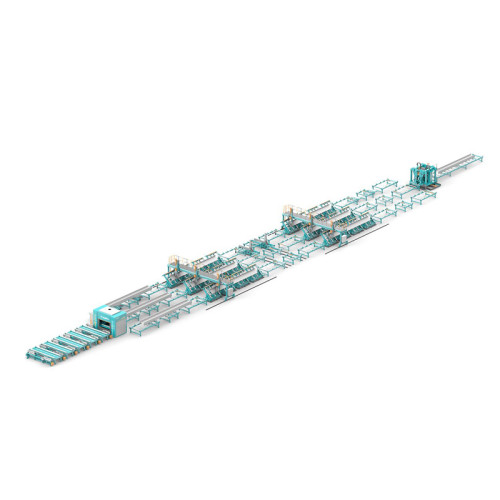

Multi-channel Horizontal H Beam Production Line

- Model

- YM-WZ-1500

Review

Description

· H-beam can be made in single process.

· Divided into horizontal assembly area, gantry welding area, and horizontal straightening area.

· once start ,The whole process will proceed automatically.

Technical Parameters

|

Model:

|

YM-WZ-1500

|

||

Workpiece material: | ≤Q355 | ||

Flange width: | 200-600mm | ||

Flange thickness: | 6-40mm | ||

Web height: | 350-1500mm | ||

Web thickness: | 6-30mm | ||

Workpiece length: | 5-12m | ||

|

Conveying speed:

|

8700mm/min

|

||

|

Welding Speed:

|

150-1500mm/min

|

||

|

Covered area:

|

120m*13.5m

|

Product Features

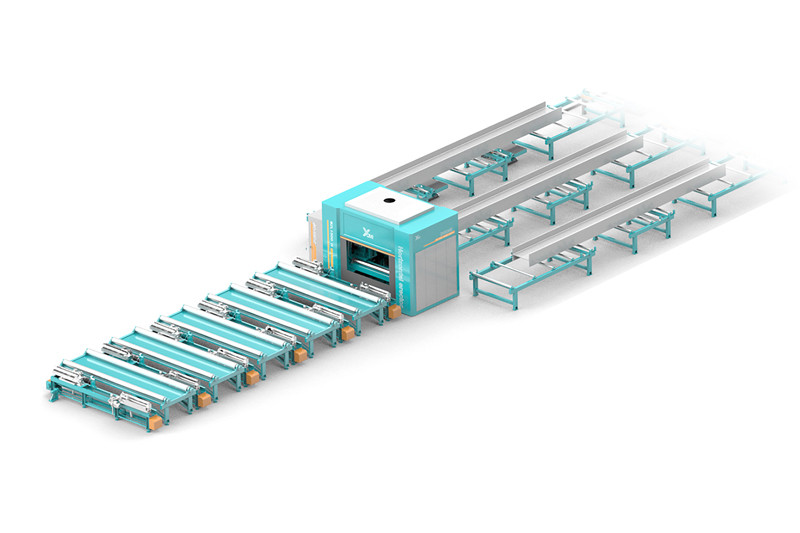

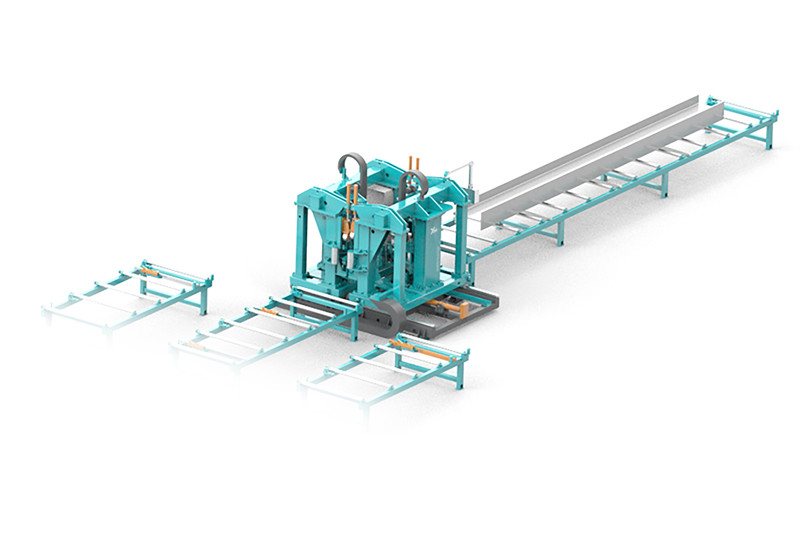

1.Horizontal assembly area

The workpiece is placed horizontally, with 2PCS 90° hydraulic turnover devices.

Synchronous clamping center the flange and web automatically.

4 welding torches start at the same time, finish making one time.

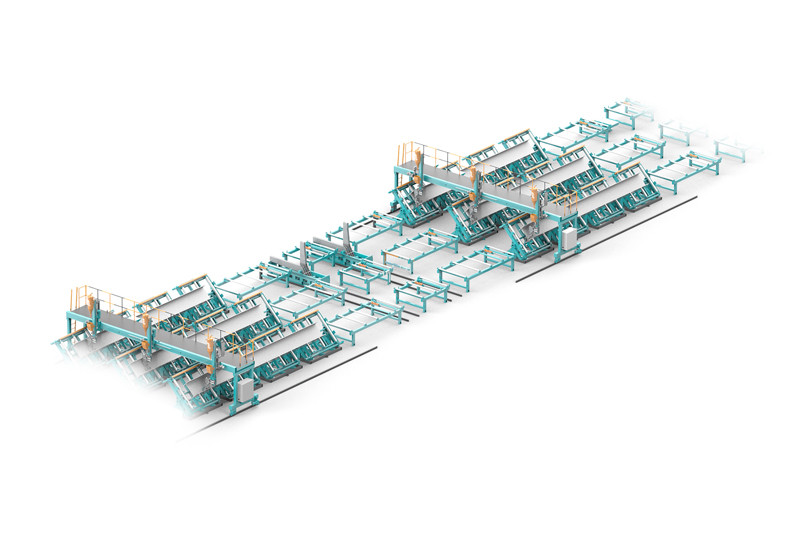

2.Horizontal welding area

Material Transported into the welding station through channels.

Multiple welder work same time, and the workpiece is turned over .

3.Horizontal straightening area

The roller conveys beam automatically into the horizontal straightening station.

Simultaneous straightening of bilateral flanges.

Automatically detect the straight,re-straighten also automatically if it is needed.

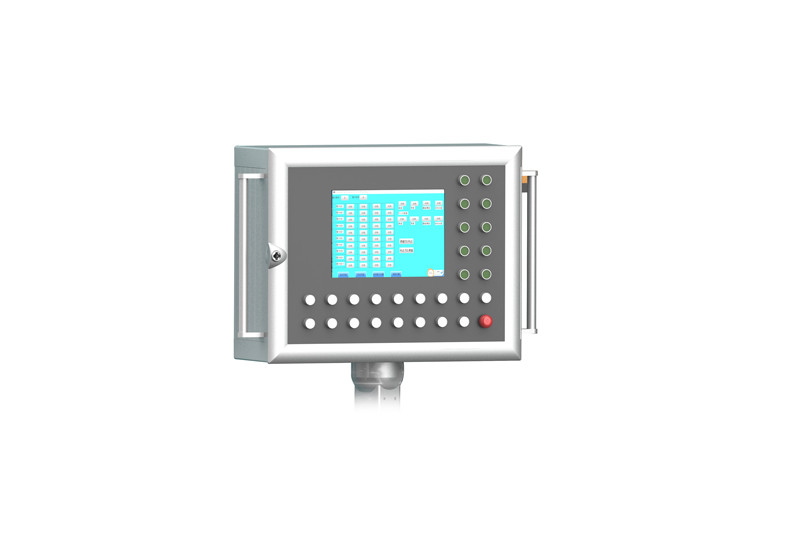

4.Intelligent Production

Intelligent production technology.

Higher automation, less manual labor required.

The whole process starts with one button.