Desktop single-sided beveling machine

Item specifics

- Power supply

- 380V/50Hz

- Total power

- 6.6KW

- Cutting main motor power

- 5.5KW/80V/50Hz

- Traveling motor power

- 1.1KW/220V/50Hz

- Spindle speed

- 1440r/min

- Processing groove speed

- 0-1.5m/min

Review

Description

Video

Product Performance

1. Higher flexibility in small piece processing, greatly

improving work efficiency.

2. Complete cold cutting processing, with no oxidationdeformation on the qroove surface.

3. Meet the requirements of welding technology and canbe processed by non-destructive testing and filming.

4. The speed during processing can be adjusted quickly

or slowly.

5. Higher efficiency than manual chamfering.

6. Wide range of bevel objects.

Technical Parameter

| power supply | 380V/50Hz | ||

| Motor Power | Total power | 6.6KW | |

| Cutting main motor power | 5.5KW80V/50Hz | ||

| Traveling motor power | 1.1KW/220V/50Hz | ||

Spindle speed | 1440r/min | ||

Processing groove speed | 0-1.5 m/min | ||

Thickness of clamping plate | 3-40mm | ||

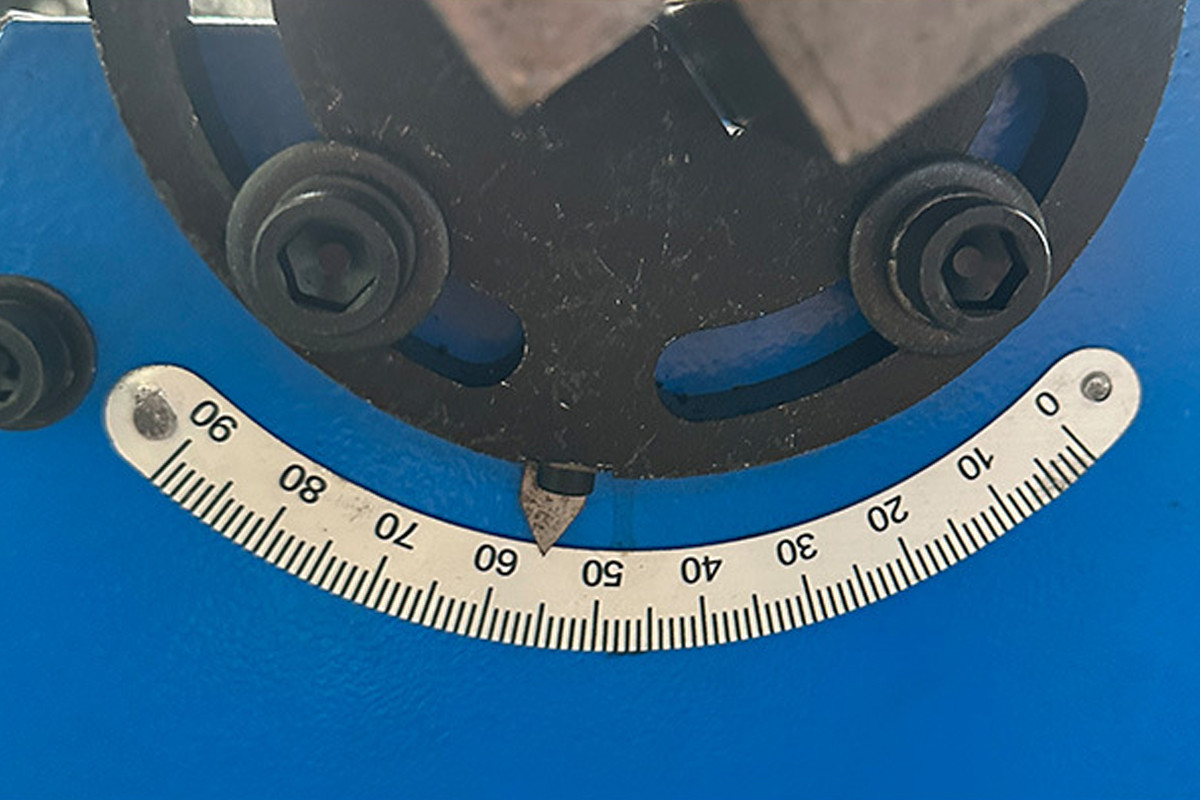

Processing groove anale | 30°-60° | ||

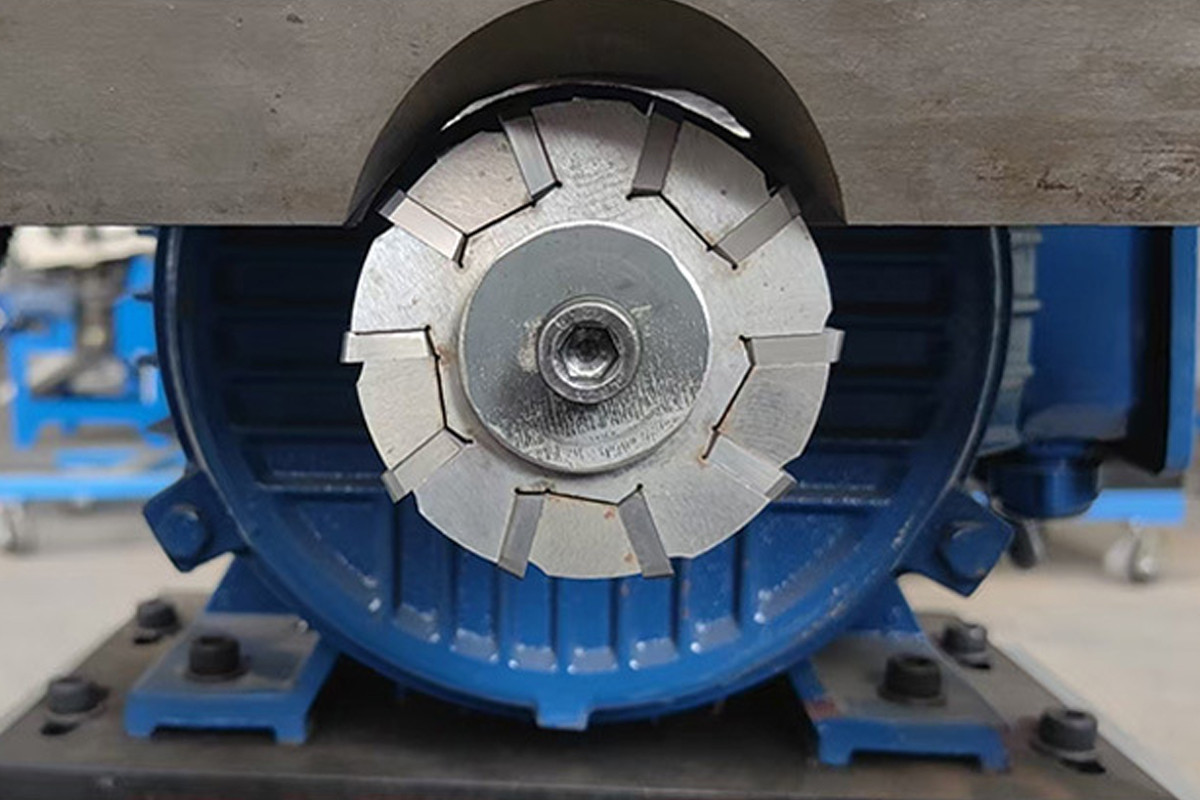

Blade diameter | 80mm | ||

Number of blades | 20 | ||

Workbench height | 800mm | ||

Single groove width | 20mm | ||

Product size | 960*810*1150 | ||

Product weight | ≈250kg | ||

Processing method | mill | ||

Processing material | Carbon steel, stainless steel, alloy steel, cast iron, aluminum plate, etc | ||

Groove smoothness | Ra3.2-6.3 | ||

PRODUCT ADVANTAGES