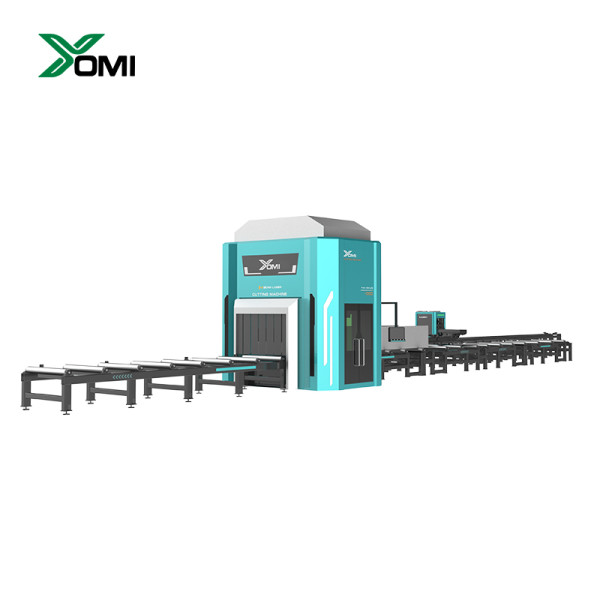

h beam fiber laser cutting machine

- Share

- Issue Time

- Dec 19,2023

Summary

The laser H-beam cutting machine is a device that uses high-energy laser beams to cut H-shaped steel materials and has been widely applied in various industries such as construction, bridge building, shipbuilding, and machinery manufacturing.

H beam Fiber Laser Cutting Machine Suitable for H-beam steel, U-beam steel, I-beam steel, slot steel and other profiles.

H-Beam Cutting Robort has been widely used in steel structure prefabricated buildings.

The laser H-beam cutting machine is a device that uses high-energy laser beams to cut H-shaped steel materials and has been widely applied in various industries such as construction, bridge building, shipbuilding, and machinery manufacturing. The current development status and advantageous features of this machine mainly include:

1.High precision and efficiency: Laser cutting machines can perform highly accurate cuts with very small error margins, and the cutting speed is fast, significantly improving production efficiency.

2.Excellent cutting quality: Compared to traditional mechanical cutting methods, laser cutting can achieve smoother and neater cutting edges, reducing the workload for subsequent processing.

3.High flexibility: It can cut H-shaped steels of various shapes, showing strong adaptability to meet the needs of complex designs.

4.High degree of automation and intelligence: Modern laser cutting machines are usually equipped with advanced CNC systems, which can achieve automated production, reduce labor costs, and enhance production efficiency and safety.

5.-saving and environmental protection: Laser cutting is a non-contact processing method with low energy consumption and does not produce a large amount of waste and dust, making it more environmentally friendly.

Low maintenance cost: Laser cutting machines are generally easy to maintain, and due to the non-contact processing method, there is less wear and tear on the machine, resulting in a longer lifespan.

With continuous technological advancements, the functions of laser cutting machines are also enhancing, such as the addition of three-dimensional cutting, remote operation, and intelligent monitoring features, to meet the ever-changing market demands.