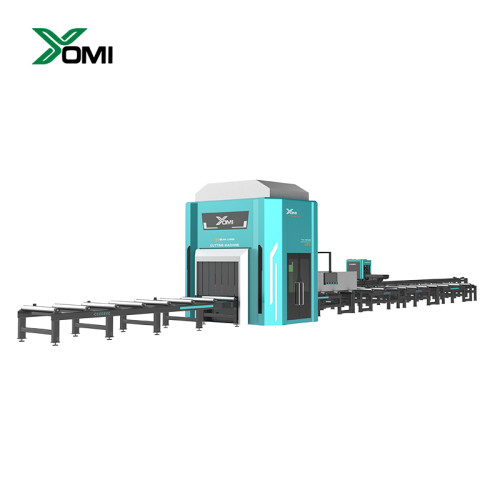

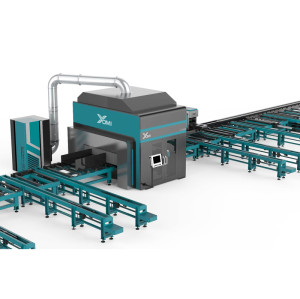

Intelligent H beam Laser Cutting Machine

- Model

- YM-XHJG-1250

Item specifics

- Flange width

- 100-600mm

- Workpiece height

- 100-1250mm

- Cutting mode

- Fiber laser

- Cutting thickness

- 1-30mm

- Bevel angle

- ±45°

- Max weight

- 6000kg

- Cutting length accuracy

- 0.05mm

- Laser power

- 20KW

- Equipment size

- 30m*10m*5m

Review

Description

H beam Laser Cutting Machine Vedio

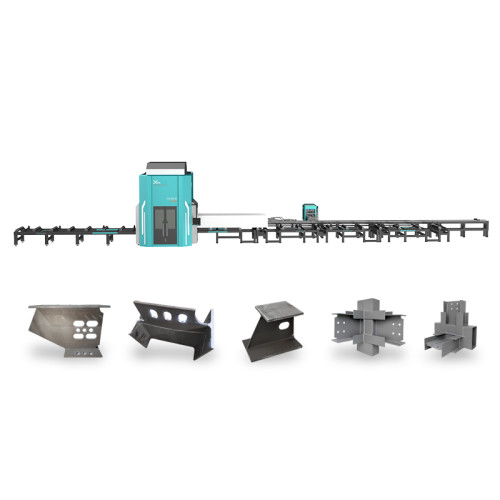

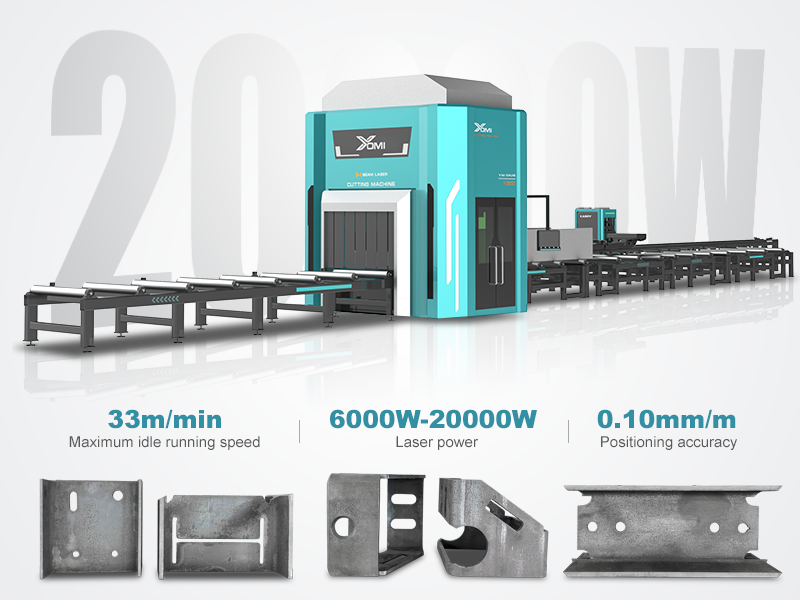

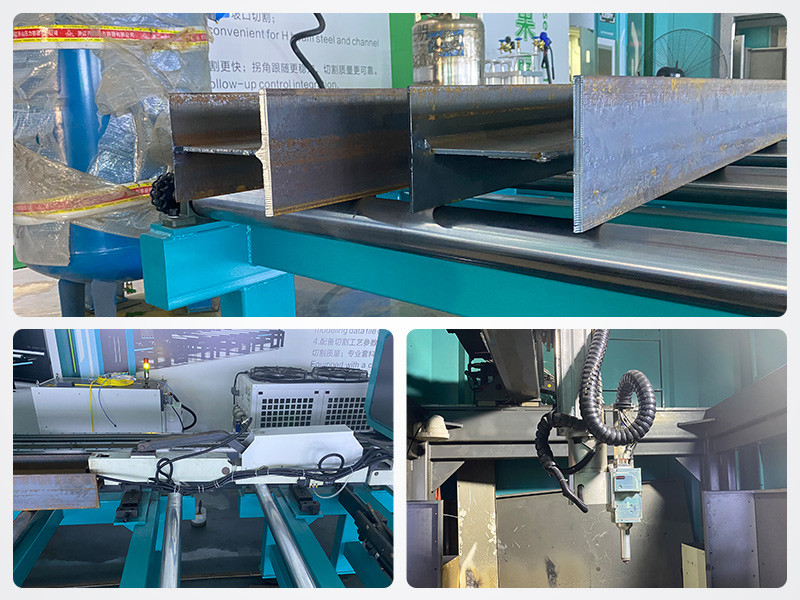

Suitable for H-beam, I-beam and Channel beam.

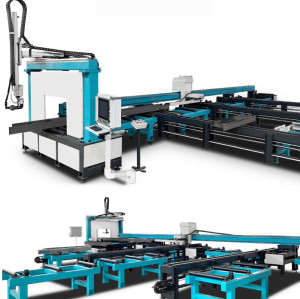

Cutting off, bolt holes,rat holes, beveling, and marking can be done in one machine.

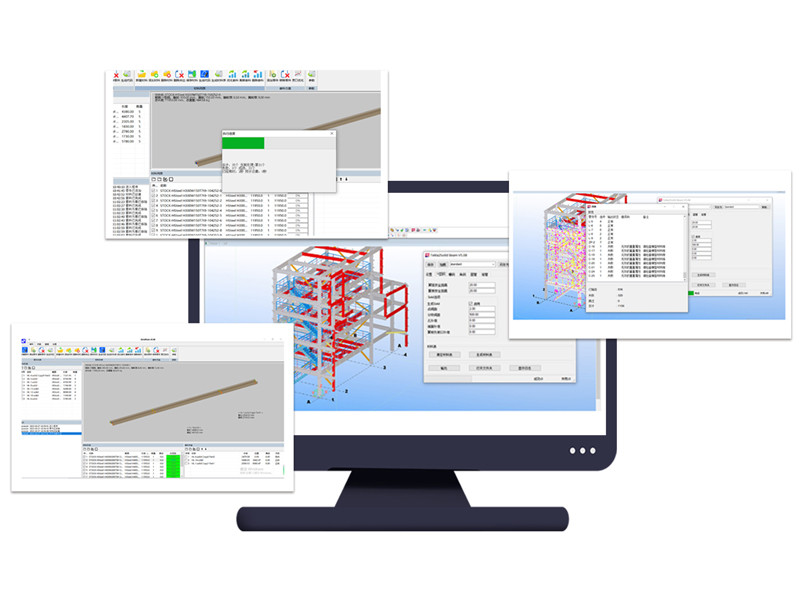

Support Tekla steel structure 3D modeling data file cutting.

H beam Laser Cutting Machine Features

Subvert Traditional Cutting Technology

More than ten years of experience in teel structure industry, better understanding of steel structure technology.

Cutting off, bolt holes,rat holes, beveling, and marking can be done in one machine.

Supports various overlapping forms of bevel cutting.

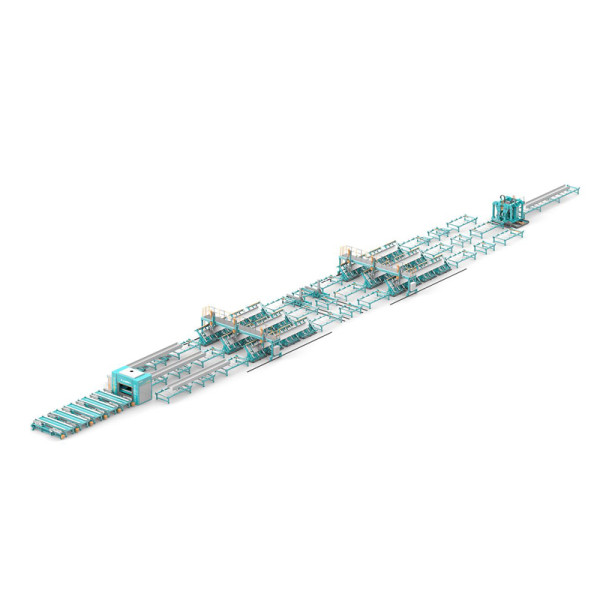

Intelligent Production

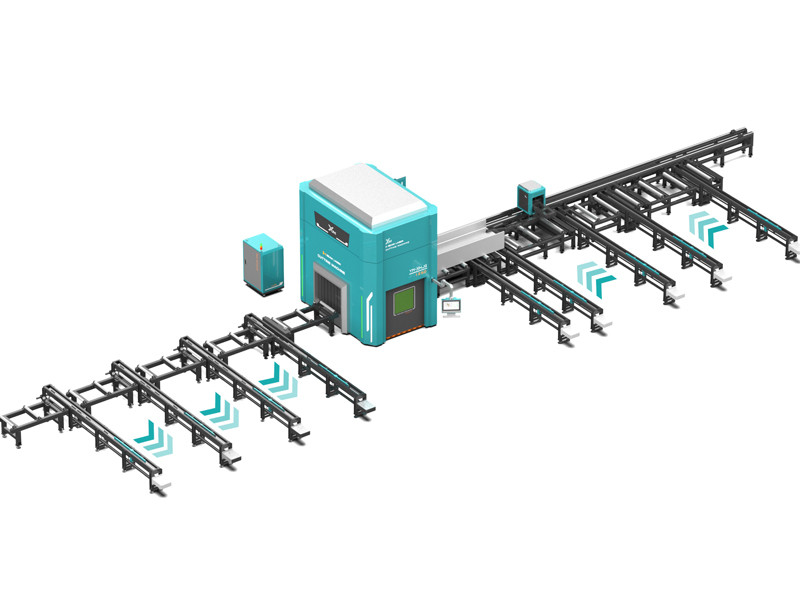

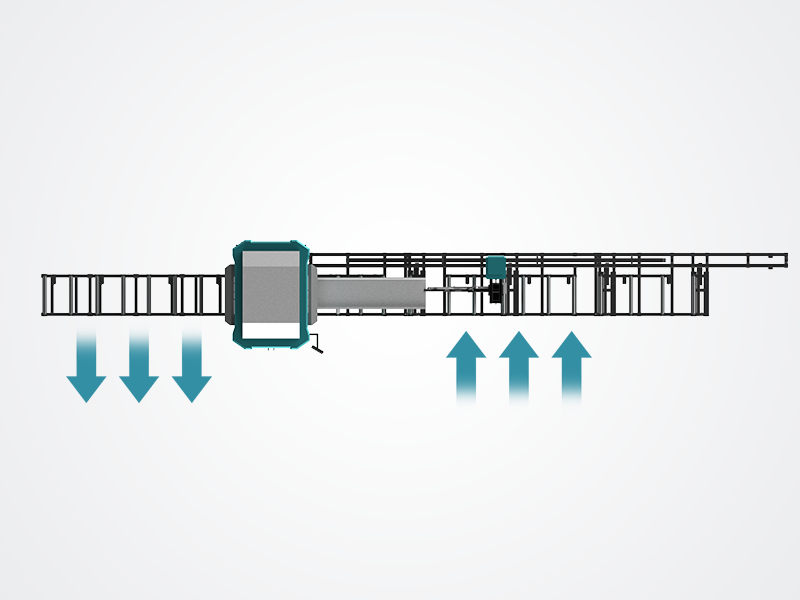

Automatic loading system, easy to load workpiece, just place beam profile on the conveyor,automatic feeding can be realized.

Full-link production technology and logistics interconnection.

Can be directly connected to MES system.

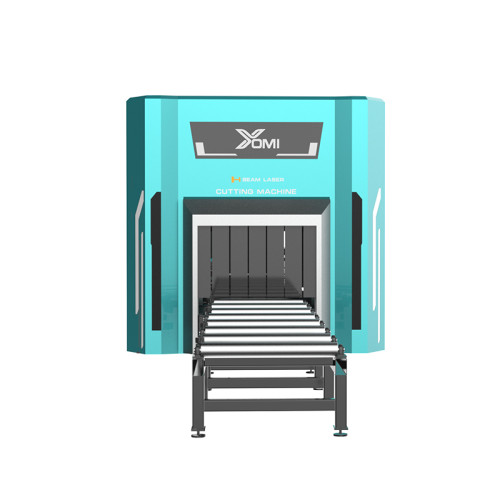

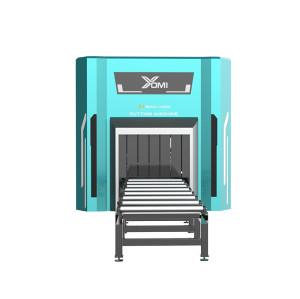

Fully Enclosed Working Environment

European level protective glass observation port, equipped with thickened sheet metal protective cover.

Laser protection level is high to ensure production safety.

High laser protection level,Ensure production safety.

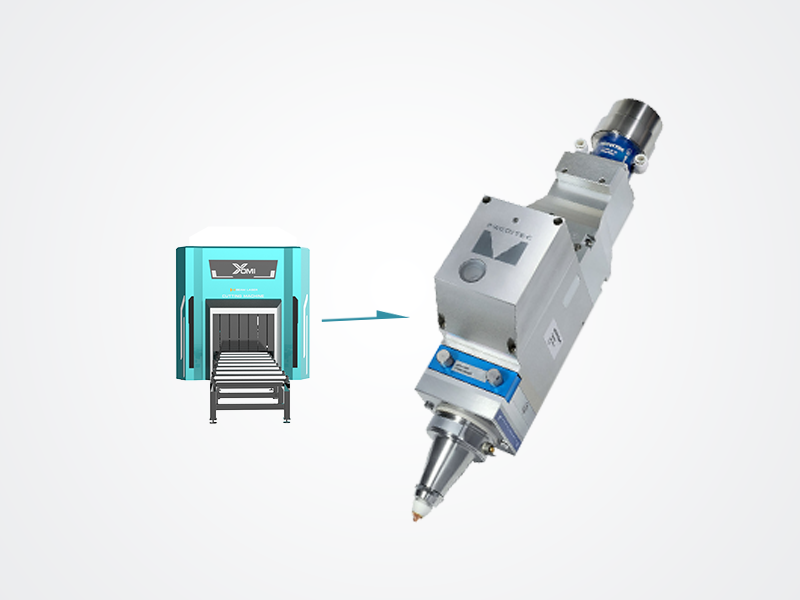

Automatic Focusing Laser Head

Equipped with Porad Laser Cutting Head

Achieve continuous focusing, rapid piercing and automatic cutting

of different thicknesses and materials of beam profiles.

Subvert Traditional Cutting Technology

Cutting off, bolt holes,rat holes, beveling, and marking can be done in one machine.

Supports various overlapping forms of bevel cutting.

Independent R&D systems

Directly connect to Tekla, automatic nesting, no need for secondary drawing

Low-code operation interface, simple and intuitive

Free software upgrade

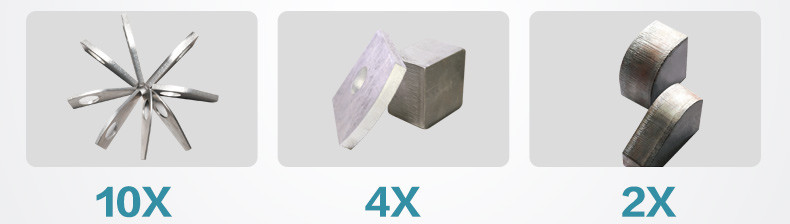

Comparison with Plasma Cutting

(1)The cutting precision is high, surface is burr-free, less cutting smoke and more environmentally friendly.

(2)Cutting thin stainless steel sheets is 10 times faster than plasma.

(3)Cutting 6mm carbon steel is 4 times faster than plasma .

(4)Cutting 12mm carbon steel is twice faster than plasma.

Application

Recommend

H-Beam Cutting Robort has been widely used in steel structure prefabricated buildings.

Multi-channel Horizontal H Beam Production Line H-beam can be made in single process.

H Beam Spraying&Painting Production Line 3D scanning can complete components of various sizes and shapes.