Plate drilling machine is an invaluable asset for steel structure processing

- Share

- Issue Time

- Jul 4,2024

Summary

The plate drilling machine is an invaluable asset for steel structure processing, offering a compelling blend of efficiency, precision, versatility, automation, reliability, improved work environment, and cost-effectiveness that surpasses traditional drilling methods.

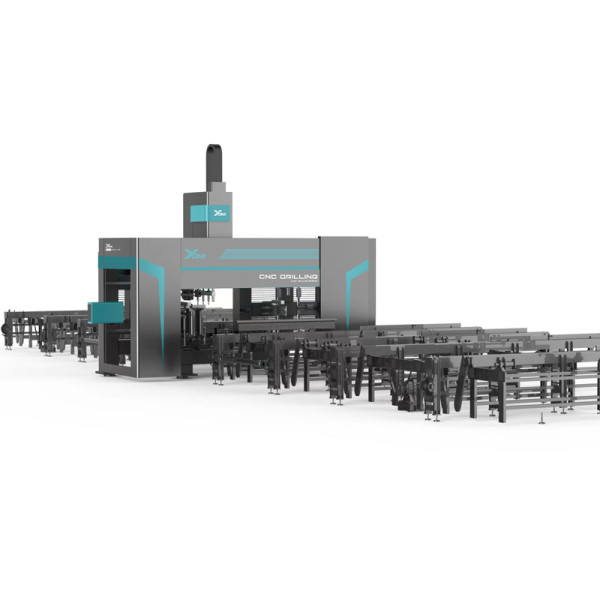

Gantry CNC Plate Drilling Machine is mainly used for drilling of connecting plates and floor board in steel structures.

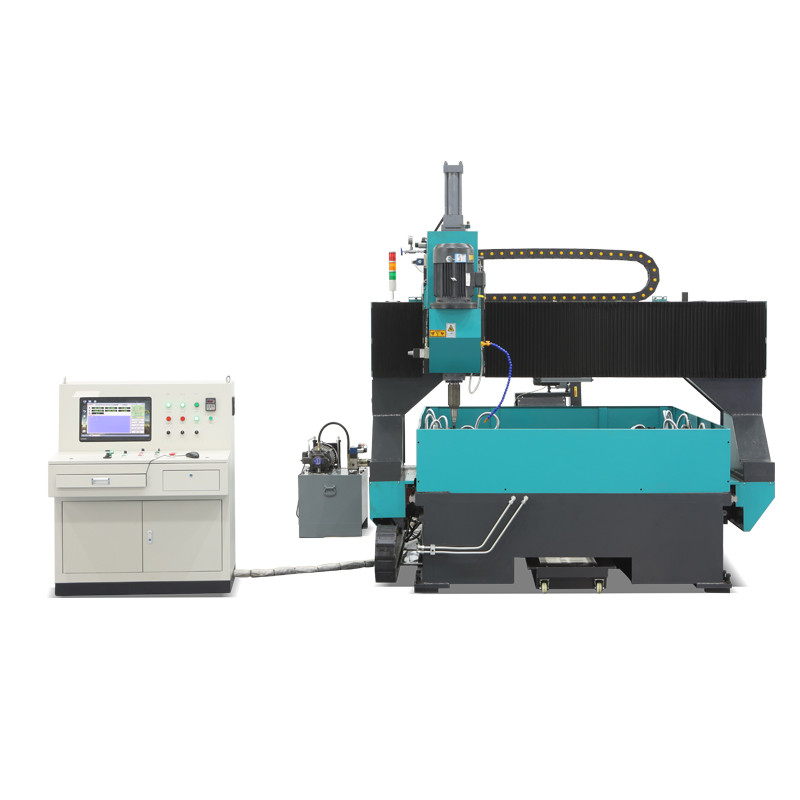

Machine tool equipment Accuracy Plasma H Beam Automatic Cutting Drilling Beveling Machine.

The plate drilling machine, within the realm of steel structure processing, represents a specialized machine tool designed for carrying out highly precise and efficient drilling operations on flat materials. Its notable advantages encompass:

Efficiency: The plate drilling machine boasts remarkable efficiency thanks to its automated and streamlined drilling process. It eliminates the necessity for manual marking, positioning, and frequent tool changes, enabling continuous and rapid drilling cycles that significantly surpass traditional drilling methods in terms of production rates.

Precision: Equipped with advanced numerical control (NC) technology and precision positioning mechanisms, the plate drilling machine ensures that hole locations and dimensions are precise. It maintains strict tolerances, ensuring compliance with or exceedance of industry standards for accuracy.

Versatility: This machine is highly versatile, capable of processing a diverse range of materials, varying thicknesses, and accommodating different hole sizes. Its modular design and interchangeable tooling facilitate swift adjustments to meet diverse job requirements.

Automation: The plate drilling machine incorporates integrated automation features that streamline the entire drilling process. From material loading and positioning to drilling and unloading, numerous tasks are automated, reducing labor costs and enhancing overall productivity.

Reliability and Durability: Crafted from high-quality materials and precision engineering, the plate drilling machine is built to endure. Its robust design ensures reliable performance even under heavy-duty conditions, minimizing downtime and maintenance requirements.

Improved Work Environment: The plate drilling machine often includes features such as dust collection and coolant systems, contributing to a cleaner and safer work environment. This not only enhances operator comfort but also prolongs the lifespan of the machine and its components.

Cost-Effectiveness: In the long term, the plate drilling machine's efficiency, precision, and durability translate into cost savings. It minimizes material waste, reduces the need for rework, and lowers labor costs associated with manual drilling methods.

In conclusion, the plate drilling machine is an invaluable asset for steel structure processing, offering a compelling blend of efficiency, precision, versatility, automation, reliability, improved work environment, and cost-effectiveness that surpasses traditional drilling methods.