Bench Type Large Pipe CNC Plasma Cutting Machine

- Model

- YM-LBP

Item specifics

- Round pipe diameter

- 108~1000mm 219~1210mm

- Cutting length

- 6000mm 9000mm12000mm

- Cutting mode

- Plasma and flame(oxy-fuel)

- Control system

- Advantech IPC with YOMI PIP

- Programming software

- Curve library, Tekla, AuotoCAD

- Driving system

- Japan Panasonic Servo Motor

- Cutting speed

- 10~2000mm/min

- Travelling speed

- 10~6000 mm/min

- Pipe Thickness(flame cutting)

- Vertical cut 6~60mm bevel cut 6-40mm

- Pipe Thickness(plasma cutting)

- Perforated cutting 1~38mm bevel cutting 1-26m

Review

Description

1.It adopts floating chuck box and roller brackets. It is convenient to load large diameter pipes and does not need to adjust the distance of rollers.

2.The centre-height of chuck is floating and adjustable,using method of chuck floating without moving of pipe,to improve cutting quality of large diameter pipe .

3.It Support Tekla, 3D3S, CAD, SolidWorks with high compatibility, directly generate G code.

4.It can cut carbon steel, stainless steel,aluminium and ect.

5.It is widely used in marine offshore engineering,oil pipeline,petrochemical and other industries.

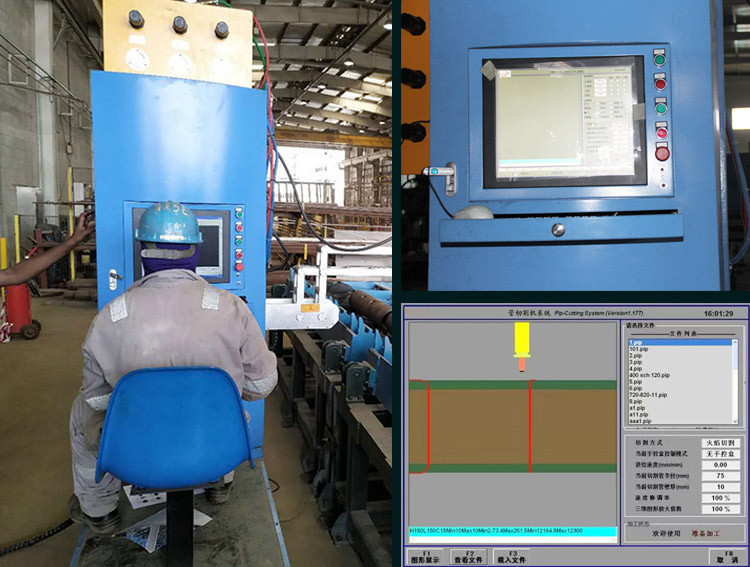

Advanced and efficient operating systems&software

Cutting arm to perform 3D cutting trajectory

High strength wheels set to level pipe and out feed

Floating 3-Jaw chuck for pipe centering and accurate rotation

Roller bed conveyors table to feed the pipes

Plasma and oxyfuel cutting torch to cut your pipes

|

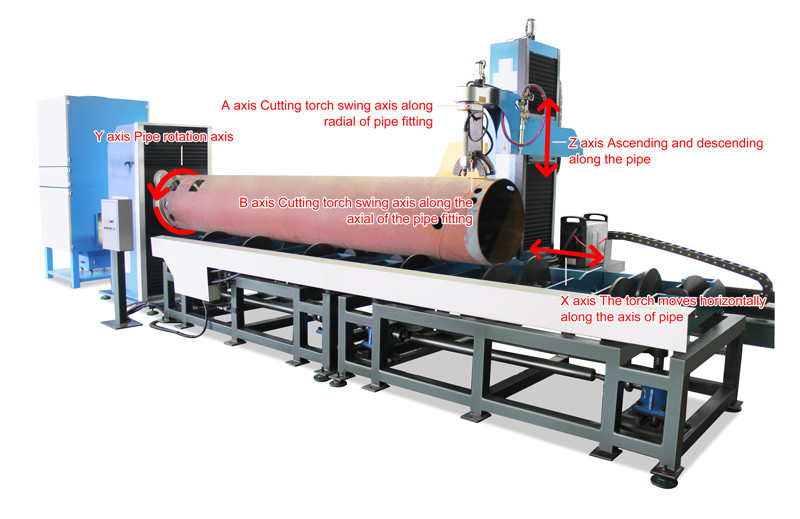

Motion Axis

|

Cutting Machine Axis Selection

|

Range of Activities

|

|

Y axis

|

Pipe rotation axis

|

360°free rotation

|

|

X axis

|

The torch moves horizontally along the axis of pipe

|

Max. stroke 10000mm

|

|

A axis

|

Cutting torch swing axis along radial of pipe fitting

|

±55°

|

|

B axis

|

Cutting torch swing axis along the axial of the pipe fitting

|

±60°

|

Z axis | Ascending and descending along the pipe | The axis does not participate in the linkage maximum stroke 830mm |

W chuck floating shaft | Chuck can be raised/lowered | External axis control lift stroke747mm |

|

Round Pipe diameter

|

219-1210mm 325-1620mm 630-2000mm

|

||

|

Torch axial swing angle |

α=±60° |

||

|

Torch radial swing angle |

β=±55° |

||

|

Cutting length accuracy

|

+1.5mm

|

||

Plasma bevel angle | plasma cutting ±45° | ||

Cutting hole diameter | 1-40inch | ||

Effective cutting length | 12000mm | ||

Required work piece ovality | ≤1% | ||

Cutting speed | 10~2000mm/min | ||

Moving speed | 10~6000 mm/min | ||

Condition temperature | -20℃ -50℃ | ||

Cutting length accuracy | ±1.5mm | ||

Frequency | 50HZ /60HZ | ||

Chuck operation mode | Manual + electric | ||

Maximum weight of pipe to be cut | 10000Kg | ||

Oblique crossing angel | 15°- 170° | ||

Angle error | 士10 | ||

Bevelangle | plasma土45° ,flame 60° | ||

Standard for execution of cutting precision | ISO9013-2002 IS08206-1991 and JB/T10045.4-1999JB |