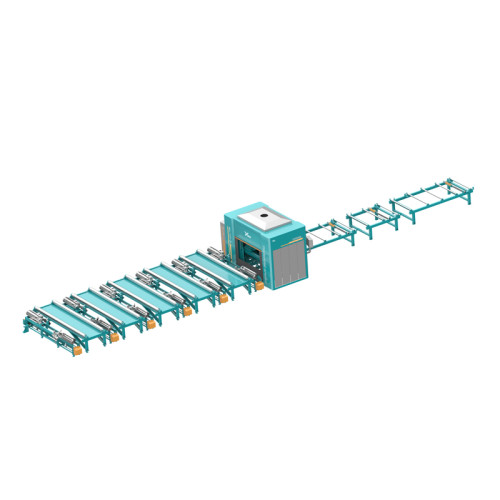

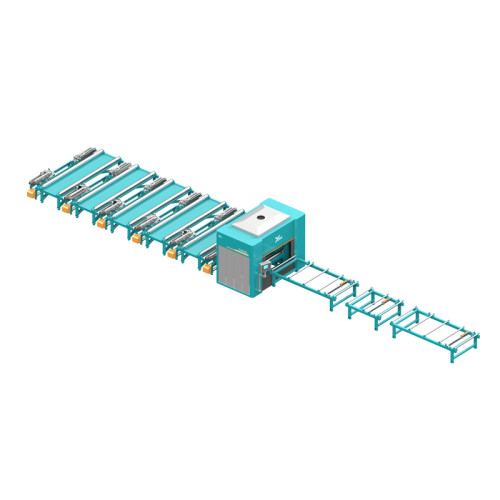

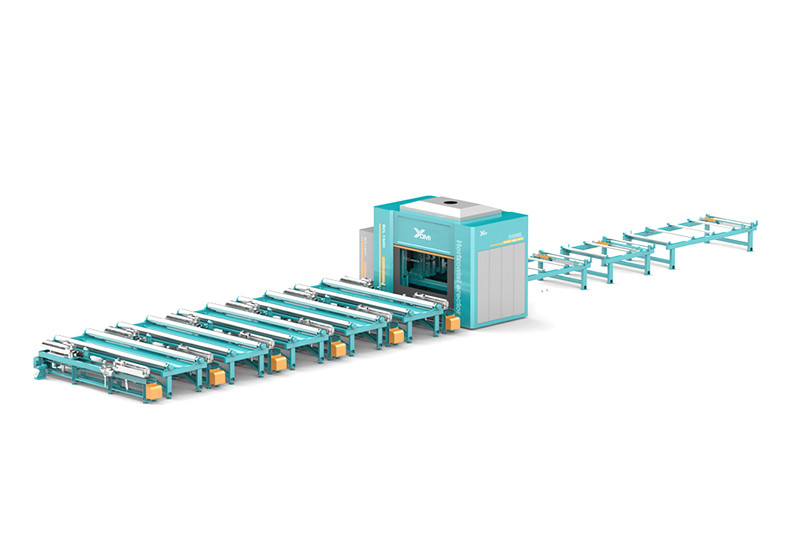

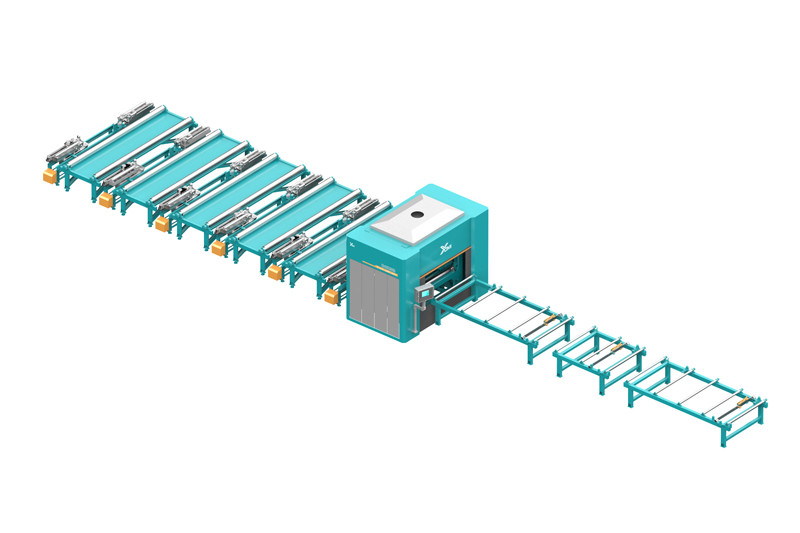

H Beam Horizontal Assembly Machine

- Model

- YM-WZL

Review

Description

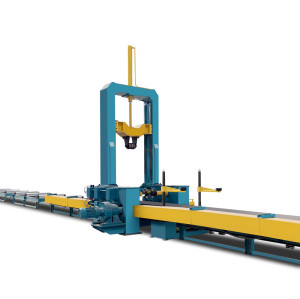

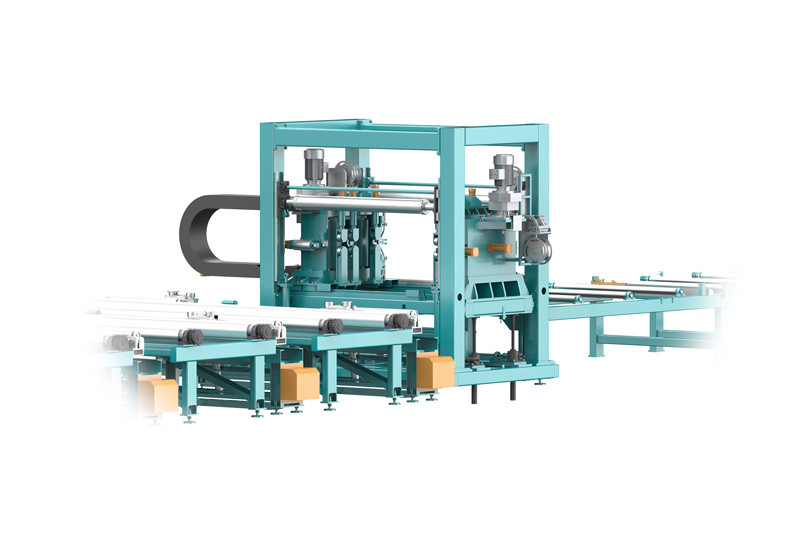

The workpiece is placed horizontally .Machine with double 90° hydraulic flip.

Synchronous clamping, automatic alignment of the web and flange.

Four pistol spot welding at the same time, one time finish work.

Technical Parameters

|

Model

|

YM-WZL

|

||

|

Component material

|

≤Q355

|

||

|

Flange width

|

140-800mm

|

||

|

Flange thickness:

|

8-40mm

|

||

Web Height: | 350-1500mm | ||

Web Thickness: | 6-40mm | ||

Workpiece length: | 5000-15000mm | ||

Conveying speed: | 8700mm/min | ||

Welding speed: | 150-1500mm/min | ||

Equipment size: | 35m*10m*4m |

Product Features

1.Strong equipment stability

The core parts are cast parts and the structure is stable.

The main drive wheel uses an integral forging process with high compression and wear resistance.

The use of centralized lubrication system, extend the service life of equipment and reduce labor costs.

2.High production efficiency

Double 90° hydraulic flip, automatic alignment of the web and flange..

Four pistol spot welding same time, the component does not need to turn over..

Vertical assembly increases efficiency by more than three times.

3.High Processing Quality

Brand Aotai/Zhenzhong welding machine.

Spot welding spacing and length fully automatic adjust.

Spot welding parameters of different specifications are automatically retrieved from the equipment parameter library.

4.Digital production

Full link to production process, logistics interoperability.

High degree of automation, without too much manual intervention.

The whole process starts with one start.