coping and cutting steel beams by using plasma

- Share

- Issue Time

- Apr 10,2023

Summary

Coping and cutting steel beams by using plasma is a highly efficient and precise method for working with steel. Plasma cutting uses a high-velocity jet of ionized gas to cut through metal, resulting in clean cuts and smooth edges.

Coping and cutting steel beams by using plasma is a highly efficient and precise method for working with steel. Plasma cutting uses a high-velocity jet of ionized gas to cut through metal, resulting in clean cuts and smooth edges. This method is particularly useful for coping steel beams, which involves cutting the end of the beam to fit into another piece of steel.

Plasma cutting machines are equipped with advanced technology that allows them to cut through steel quickly and accurately, with minimal waste. The machines are computer-controlled, ensuring that every cut is precise and consistent. This makes plasma cutting an ideal choice for large-scale projects where precision and speed are essential.

Overall, coping and cutting steel beams by using plasma is a powerful and versatile method that can significantly improve efficiency and quality in steel fabrication. Whether you're working on a construction site or in a manufacturing facility, utilizing plasma cutting technology can help you get the job done faster and more effectively than ever before.

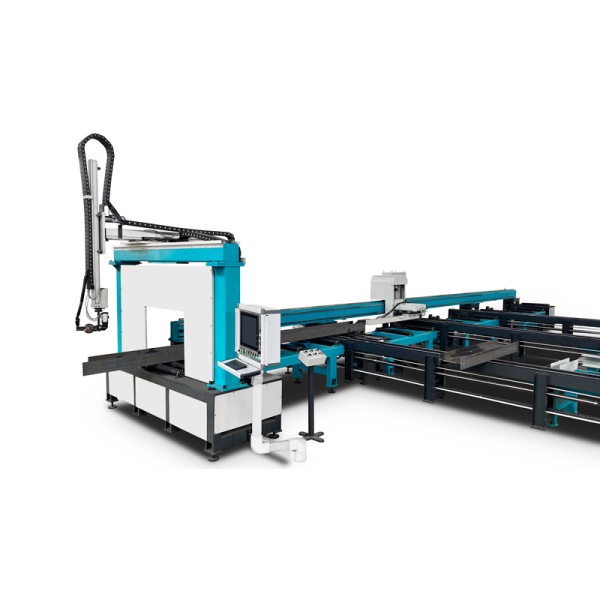

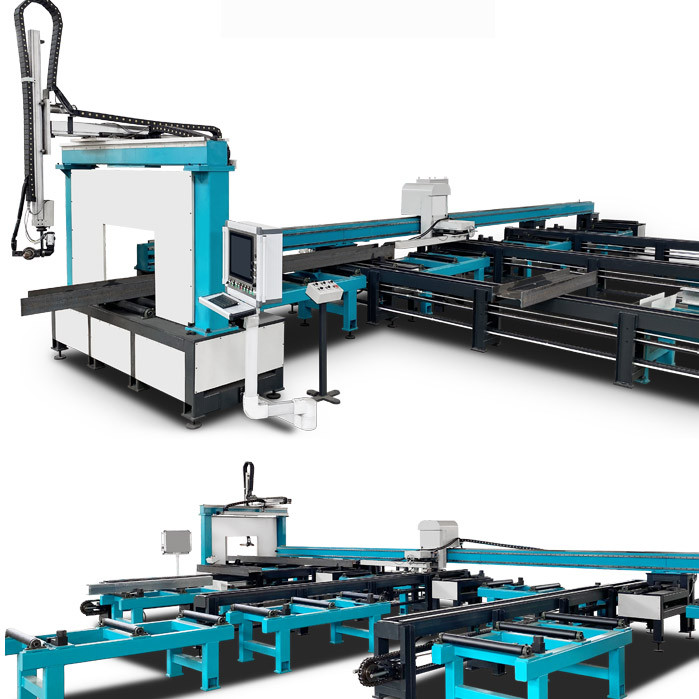

H-Beam Cutting Robort has been widely used in steel structure prefabricated buildings

H Beam CNC Plasma Cutting Machine is mainly used for cutting of steel structure enterprises