H Beam Plasma Profile Cutting Robot Machine

- Model

- YM-600,YM-1000, YM-1250, YM-1500

Item specifics

- Cutting method

- Plasma/Flame

- Plasma power source

- Herpertherm XPR300A

- Plasma cutting thickness

- Pierce cutting thickness 1-45mm

- Oxy fuel cutting thickness

- Vertical cutting thickness 6-32mm

- Effective cutting length

- 12m

- Cutting precision in length

- ±1.5mm

- Beam Web Height(YM-600)

- 100-600mm

- YM-1000

- 100-1000mm

- YM-1200

- 200-1250mm

- YM-1200

- 200-1250mm

- Beam flange width

- 100-600mm

Review

Description

Description

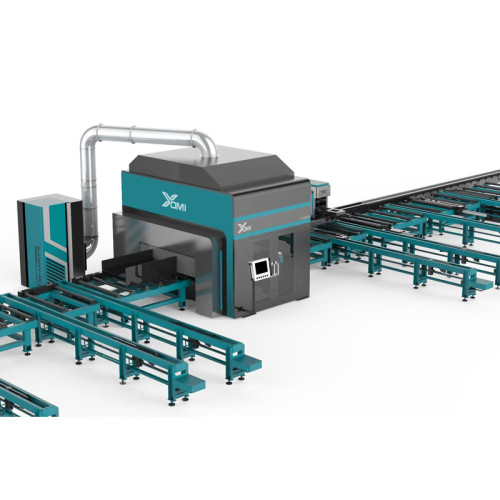

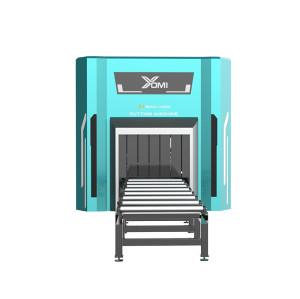

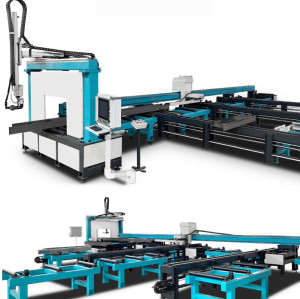

CNC Beam Plasma Cutting Machine

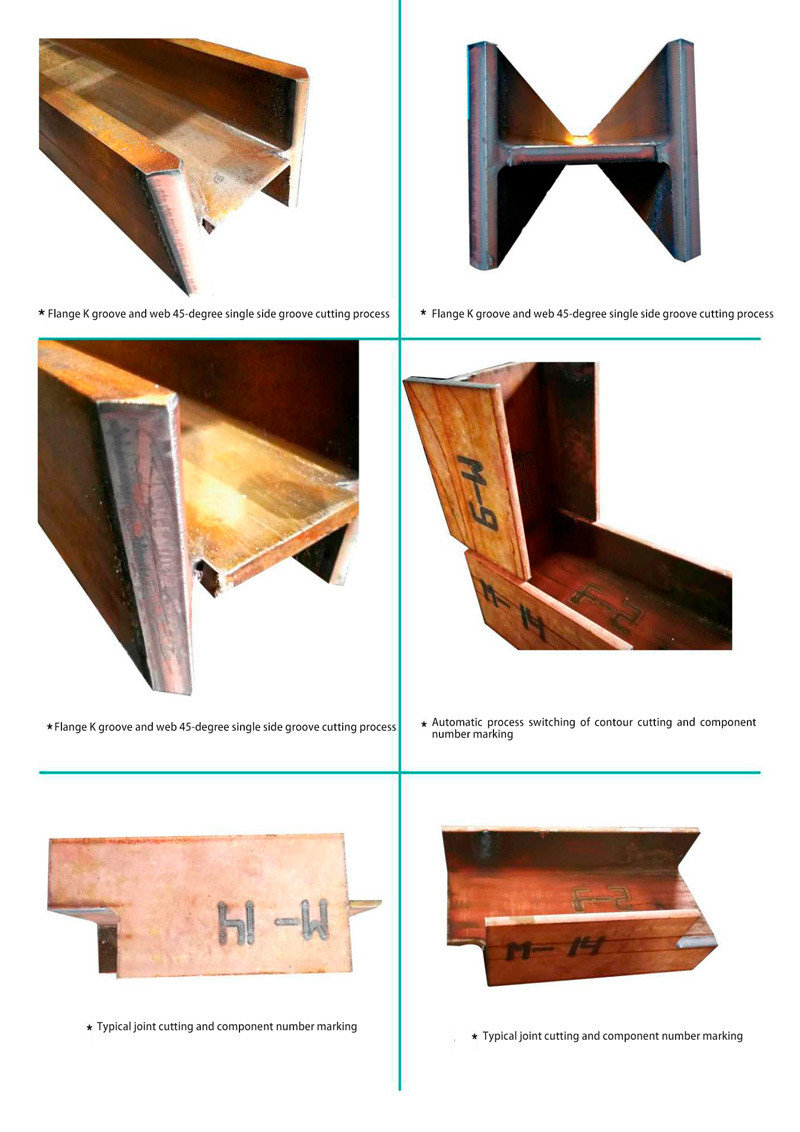

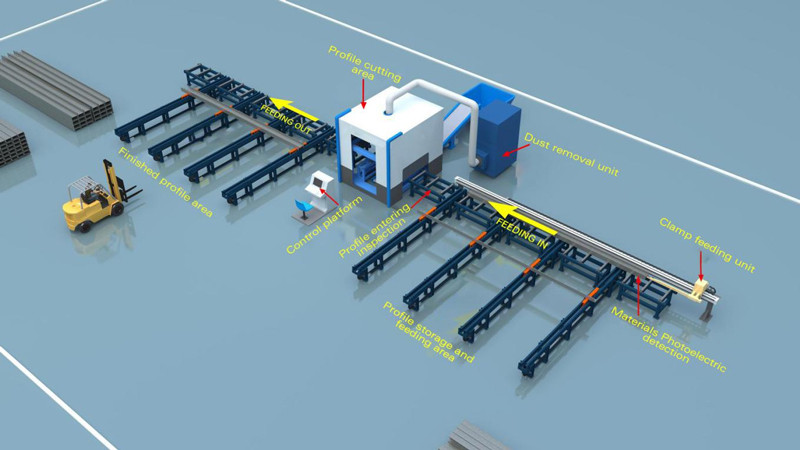

Application:Profile Plasma Cutting Machine is consisted of cutting unit, roller frame,feeding trolley and rail, finished profile conveying station. It is a hot cutting processing equipment for H beam, I beam, Channel steel, Angle steel,and their inter-sectioning shape.

Applicable materials:Carbon structural steel, stainless steel

Technical Parameters

|

H beam/I beam/Channel steel/angle steel

|

YM-XH-600 | 100-600mm |

|

YM-XH-1000 | 100-1000mm | ||

YM-XH-1200 | 200-1250mm | ||

YM-XH-1500 | 600-1500mm | ||

Cutting method | Plasma/Flame | ||

Plasma power source | Herpertherm XPR300A | ||

Plasma cutting thickness | Pierce cutting thickness 1-45mm | ||

Oxy fuel cutting thickness | Vertical cutting thickness 6-32mm | ||

|

Cutting speed

|

10~2000mm/min

|

||

|

Moving speed

|

10~6000 mm/min

|

||

Maximum profile weight to be cut |

5000Kg Note:Can customized according to offered max weight

|

||

Beveling cutting | ±45 degree | ||

Profile cutting form | Fixed length straight cut, fixed length oblique cut and end socket function | ||

Cutting accuracy execution standard | ISO9013-2002\ISO8206-1991\ JB/T10045.4-1999JB | ||

Cutting Efficiency Measurement

Profile specifications:

340*250 as below drawing.( Max cutting length 3500mm. The main cutting process includes single and double-sided beveling, over-welded hole and web shaped track)

Adopt hypertherm XPR300 fine plasma power source 170A current, Process No. 1152 Air + Oxygen

Provides stable source pressure and flow (air + oxygen) on site

Cutting result record:

1.Single structural profile cutting time is 8 minutes.

2.The distance between the two over-welded holes is 6-8 mm.

FEATURES

Cutting Station

Profile Feeding Unit and Traverse Frame

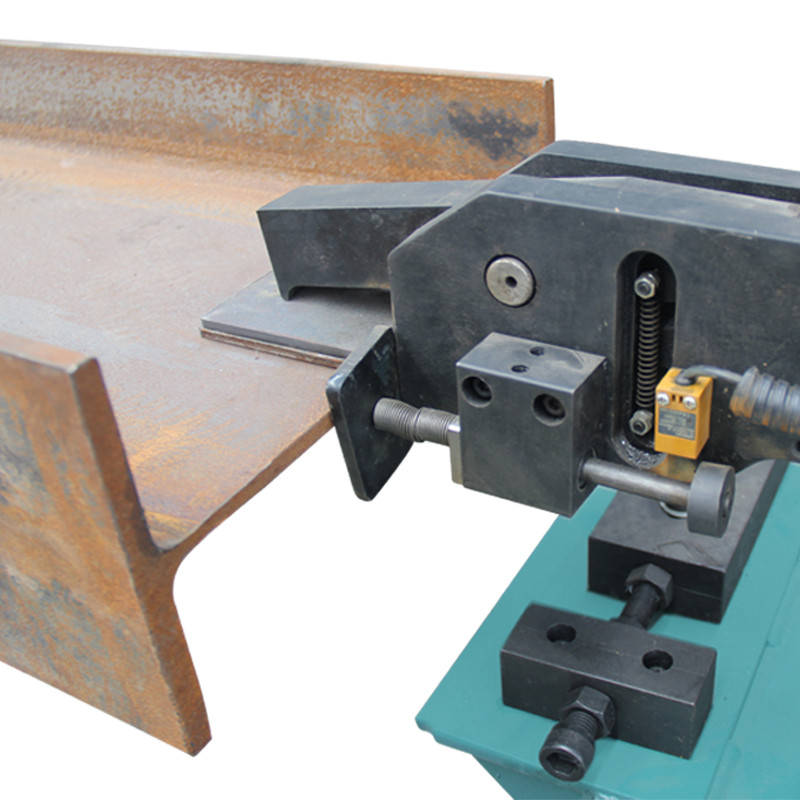

Clamp Feeding Unit

Finished Profile Feeding Out and Storage Area

Laser test function introduction

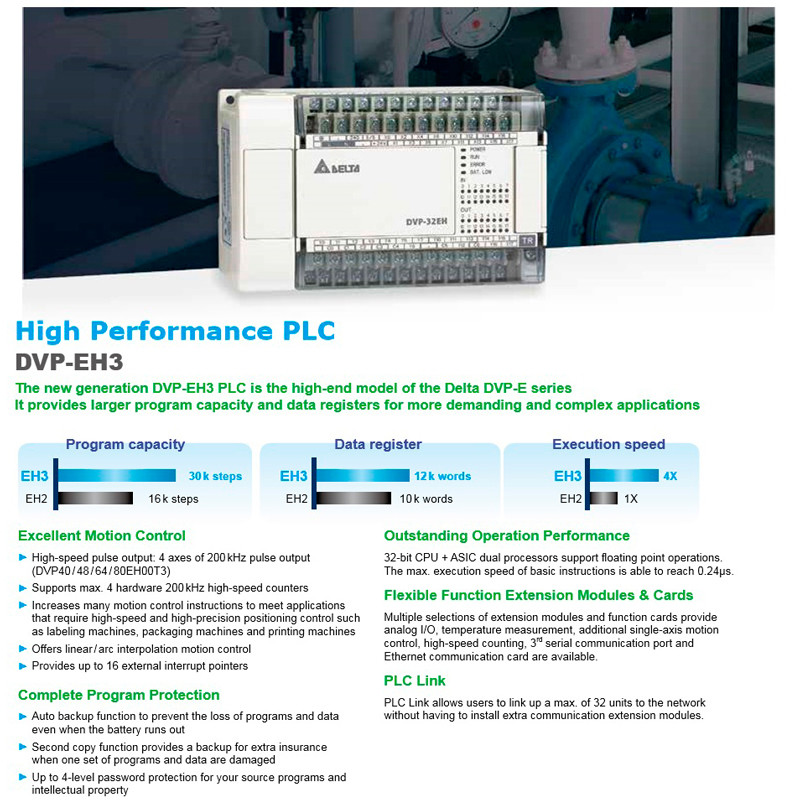

Human Machine Interface,Clear touch screen

VEDIO

Application

Customers’ Project

Customers’ Project