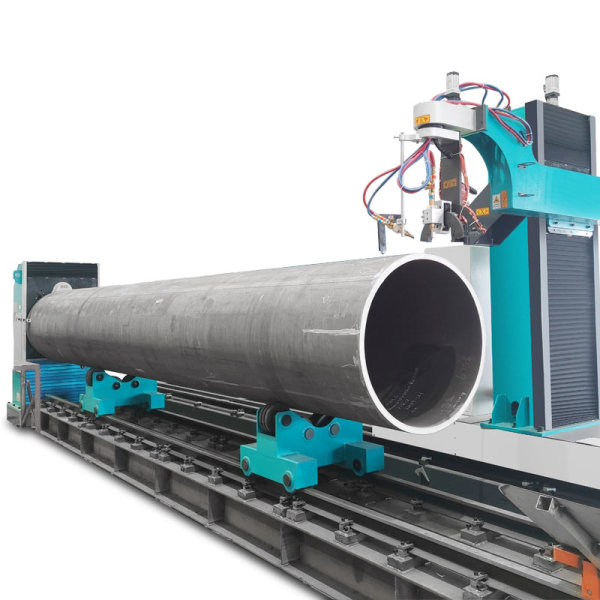

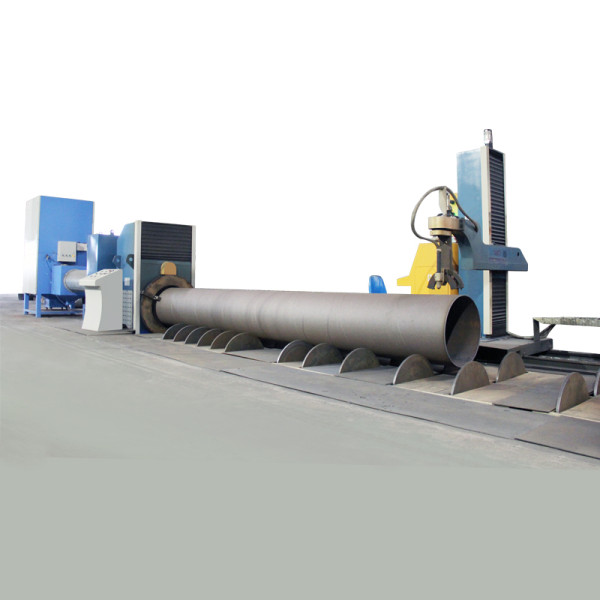

Roller model Large Pipe Cutting Machine

- Share

- Issue Time

- Oct 26,2023

Summary

5 axis series CNC pipe plasma cutting machine is a device that automatically calculates and cuts the joints of the ends of steel pipes. The machine can be widely used in the cutting and processing of pipeline structural parts in shipbuilding, construction, petrochemical, machinery, metallurgy and other industries.

5 axis series CNC pipe plasma cutting machine

CNC pipe plasma cutting machine is a kind of equipment that automatically calculates and cuts the joints of steel pipe ends.

Bench Type Large Pipe CNC Plasma Cutting Machine Visual operating platform,Simple and intuitive operation software.

5 axis series CNC pipe plasma cutting machine is a device that automatically calculates and cuts the joints of the ends of steel pipes. The machine can be widely used in the cutting and processing of pipeline structural parts in shipbuilding, construction, petrochemical, machinery, metallurgy and other industries. In these industries, there are a large number of pipes combined with intersecting line holes, intersecting line ends, and elbows commonly known as "shrimp knots". Most of such processing uses model making, scribing, manual lofting, manual cutting, manual grinding, etc. Backward and complicated methods. The 5 axis series CNC pipe cutting machine manufactured by our factory can cut such workpieces very conveniently, and the operator does not need to program, only need to enter the parameters of the radius and intersection angle of the pipe, and the machine can automatically cut the pipe. The intersecting lines, intersecting holes, and welding grooves no longer need manual grinding.

5 axis series CNC pipe cutting machine adopts cylindrical coordinate coefficient control, and the number of control axes is 5 axes. With Chinese and English interface, parameter input and man-machine dialogue function, fixed-angle bevel surface cutting function, variable-angle bevel surface cutting function, cutting speed change automatic control function, etc.

The CNC control interface of the 5 axis series series CNC pipe cutting machine combines graphics and data, and the operation is very simple: the operator only needs to enter the radius, intersection angle, cutting speed and other parameters of the supervisor and branch pipe into the computer to automatically generate the processing code. The software is designed with reasonable cutting lead-in and lead-out lines to ensure the quality of the cutting surface. The parameters after each cutting can be saved as a file for the same workpiece in the future.

5 axis series CNC pipe cutting machine can choose oxyacetylene gas cutting, oxygen liquefied petroleum gas gas cutting or plasma cutting according to user requirements. The maximum and minimum cutting pipe diameter and pipe length can be designed and manufactured according to user requirements.

The workflow of the device:

(1) Programming

Can be programmed directly on the machine or offline editor. Use menu selection to input cutting parameters, such as outer diameter, wall thickness, bevel angle, compensation data, etc. Programming can also be implemented through nesting software. The CAD graphics imput nesting software directly generates the cutting program in DAA format, which can be cut by copying it to the device control system through the U disk.

(2)Feeding the tube

Adjust the chuck and jaw up and down according to the pipe diameter, and place the pipe on the loading roller frame with a lifting tool. Manually push the tube to the chuck. The end of the pipe reaches the clamping place of the chuck, and then it is manually clamped with a wrench to complete the feeding.

Tubes of different diameters are placed directly on the support roller frame, regardless of the axial level.

(3) Measurement Horizontal angle

Because the fixed two-stage double-row friction wheel is used to support the tube, it is only necessary to place the tube on the bracket without leveling, and no manual leveling is required, which greatly improves the work efficiency.

(4) Pipe locking

Manually adjustable three-jaw self-centering chuck supports the inner diameter of the tube. The elongated concave claw is used to facilitate the beveling of the pipe end.

(5) Start cutting

Move the cutting head to the pipe end for cutting, the device will automatically position according to the program for the next cutting, and complete all cutting procedures according to the programming. When cutting the hole at the end of the pipe, rotate the pipe to the non-claw position to avoid cutting to the claw.

All hole-drilling benchmarks are based on the same cylinder end face. The hole-drilling program can cut the hole radially according to the entire circumference and then cut the hole longitudinally, or cut the hole on the same center line longitudinally and then cut the radial hole or both. Various ways of cutting. After cutting the large hole, it will not affect the rotation of the pipe due to the support at other positions of the pipe.

Description of equipment use

1.1 Mainly used for thermal cutting of intersecting lines and ends of various piping systems.

1.2 Applicable workpiece material: low carbon steel (copper nickel tube and stainless steel tube need to be plasma cut)

III. Equipment characteristics

3.1 Yomi professional pipe optimization CNC system has, AutoCAD version engineering design drawings can directly generate CNC machine tool processing codes.

3.2 Support pipe fitting splitting/mirror/left-right replacement and other pipe fitting optimization functions.

3.3 Support TEKLA software to seamlessly generate CNC machining codes.

3.4 The biggest feature of the lifting structure of the spindle box is that the center height of the chuck is floating and adjustable, and the method of floating the chuck without moving the tube is adopted to improve the cutting quality of large diameters.