WHAT IS BEAM COPING?

- Share

- Issue Time

- Dec 4,2023

Summary

Structural steel is used in the construction of just about every kind of structure, including buildings, bridges, and ships. And, of course, designs of these structures can vary greatly. To precisely match specifications outlined in blueprints, steel beams must be fabricated to perfection. In addition to being cut to size and thickness, steel beams often need to be coped to meet the structural support needs of the project.

WHY BEAM COPING IS IMPORTANT

Structural steel is used in the construction of just about every kind of structure, including buildings, bridges, and ships. And, of course, designs of these structures can vary greatly. To precisely match specifications outlined in blueprints, steel beams must be fabricated to perfection. In addition to being cut to size and thickness, steel beams often need to be coped to meet the structural support needs of the project.

WHAT IS BEAM COPING?

Coping refers to the process of cutting slots or other indentations into steel beams so that they tightly interlock with other beams. Beam coping allows for more flexibility in architectural design, as it makes acute and obtuse angles of intersecting beams possible without jeopardizing the strength of the structural steel frame.

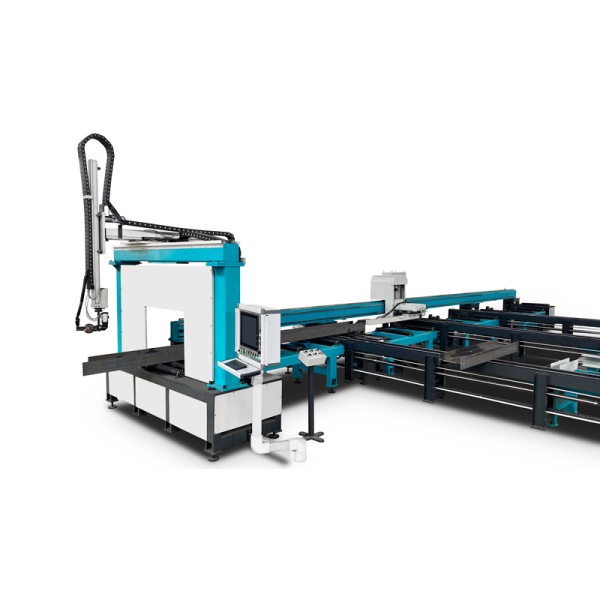

H-Beam Cutting Robort has been widely used in steel structure prefabricated buildings.

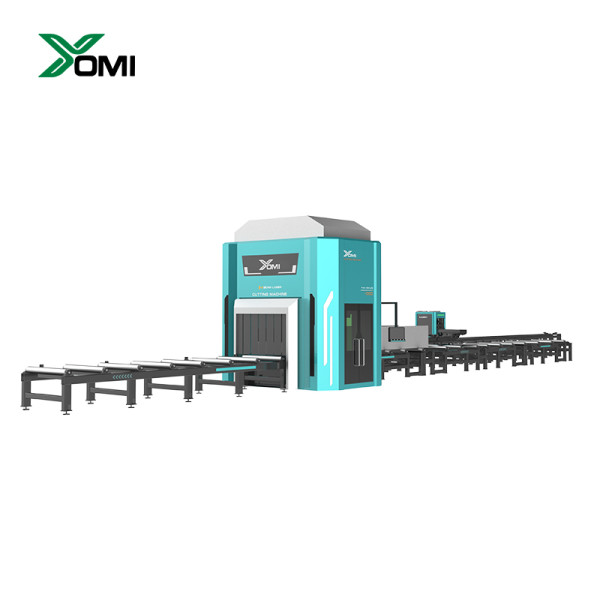

H beam Fiber Laser Cutting Machine Suitable for H-beam steel, U-beam steel, I-beam steel, slot steel and other profiles.

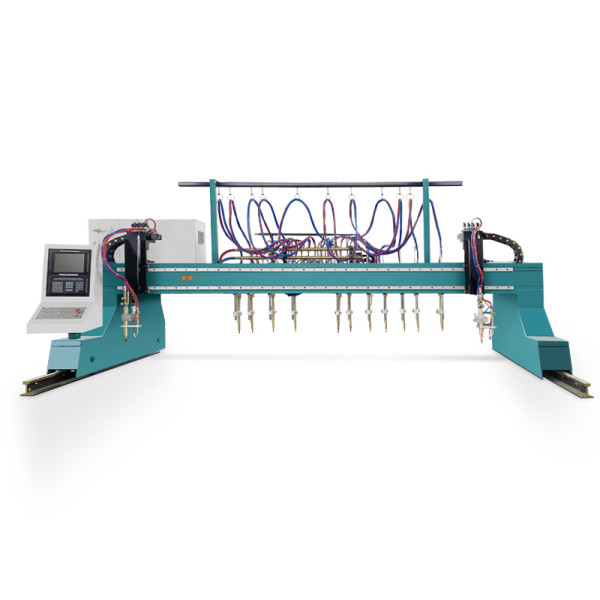

H Beam CNC Plasma Cutting Machine is mainly used for cutting of steel structure enterprises

The equipmte carbon steel for vertical and straight cutting to improve cutting efficiency.

HOW IS BEAM COPING DONE?

Skilled metalworkers can cut reliefs into steel beams by hand using a blowtorch. However, coping by hand is a time-consuming, expensive, and often imprecise process. Most structural steel fabricators use a CNC beam coping machine to perform this task. CNC beam machines eliminate the potential for error that is always a risk with a handheld torch, and they automate the cutting process, delivering much quicker results than any human—no matter how skilled—is capable of.

THE INDUSTRY’S LEADING CNC BEAM COPING MACHINE

Professionals looking to invest in industry-leading structural steel and plate fabrication technology rely on BeamCut. This remarkable CNC beam coping machine is decked out with state-of-the-art features that can help fabrication shops reach the next level of success. These features include:

A six-axis robotic arm that can bevel 360 degrees and cut any shape or profile in the industry

One of the most powerful plasma systems on the market

User-friendly CNC software that automates beam coping and other fabrication processes

BENEFITS OF BEAMCUT

Precise beam coping measurements can be programmed into the CNC software and cutting tests can be ran in the digital environment to prevent any errors in the fabrication process. Then, it’s simply a matter of loading the beam and pressing the start button for BeamCut to take over and deliver 100% accurate cuts. This easy operation helps structural steel and plate fabrication shops maintain a lean workforce because BeamCut only requires one technician to operate. And because this impressive beam machine is automated, it help reduce production time by 80%, a significant return on investment!