Laser steel cutting machines have significant advantages

- Share

- Issue Time

- Jun 26,2024

Summary

Compared to traditional cutting equipment, laser steel cutting machines have significant advantages. Here is a detailed explanation of the benefits of laser steel cutting machines

Compared to traditional cutting equipment, laser steel cutting machines have significant advantages. Here is a detailed explanation of the benefits of laser steel cutting machines:

High Precision: Laser cutting utilizes high-energy-density laser beams for processing, achieving exceptionally fine cuts. The focal diameter of the laser beam is extremely small, and it can be precisely controlled by a computer, resulting in extremely high cutting accuracy that meets the precise cutting requirements of complex patterns.

High Efficiency: Laser cutting has a fast speed and does not require contact with the workpiece during the processing, reducing wear and tear and tool replacement time compared to traditional cutting methods. Furthermore, laser cutting machines can operate continuously, greatly improving production efficiency.

Strong Material Adaptability: Laser cutting can handle various materials, including metal materials such as stainless steel, carbon steel, alloy steel, aluminum, and copper, as well as non-metals like plastics and wood. Especially for difficult-to-process materials, such as those with high hardness and brittleness, laser cutting can handle them with ease.

Environmental Protection and Energy Saving: Laser cutting does not require the addition of coolant during the processing, and the cutting process generates less heat, reducing energy consumption. Additionally, laser cutting produces minimal waste that is easily recyclable, contributing to environmental protection.

High Degree of Automation: Modern laser cutting machines are typically equipped with advanced CNC systems, enabling automated operation. Through programming, the machine can automatically complete complex cutting tasks, reducing the need for manual operation and lowering labor intensity.

Excellent Cutting Quality: Laser cuts have smooth and even edges, requiring no secondary processing. Moreover, due to the high energy density of the laser beam, the heat-affected zone during cutting is small, minimizing the impact on the material's properties.

Flexible Processing: Laser cutting machines can be flexibly adjusted based on actual needs, such as changing cutting speed, power, and other parameters to adapt to different material cutting requirements. Additionally, laser cutting machines can be integrated with other equipment (e.g., robots, conveyor lines) to achieve flexible production.

Reduced Maintenance Costs: Laser cutting machines have a relatively simple structure, making maintenance convenient. Additionally, due to the excellent focusing performance of the laser beam, the machine is less prone to wear or failures during long-term operation, reducing maintenance costs.

In summary, laser steel cutting machines have been widely applied in industrial production due to their advantages such as high precision, high efficiency, strong material adaptability, environmental protection and energy saving, high automation, excellent cutting quality, flexible processing, and reduced maintenance costs.

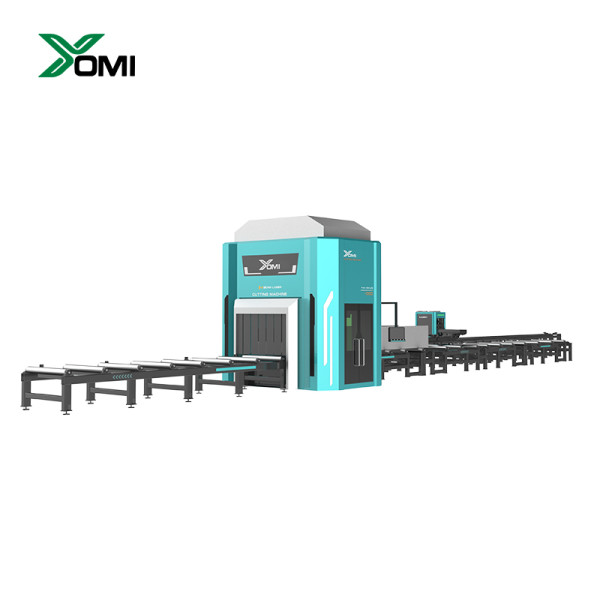

H beam Fiber Laser Cutting Machine Suitable for H-beam steel, U-beam steel, I-beam steel, slot steel and other profiles.

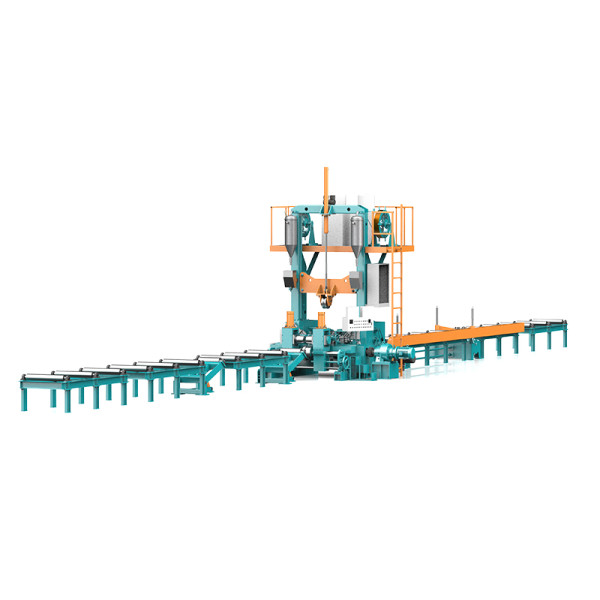

H-Beam Cutting Robort has been widely used in steel structure prefabricated buildings.

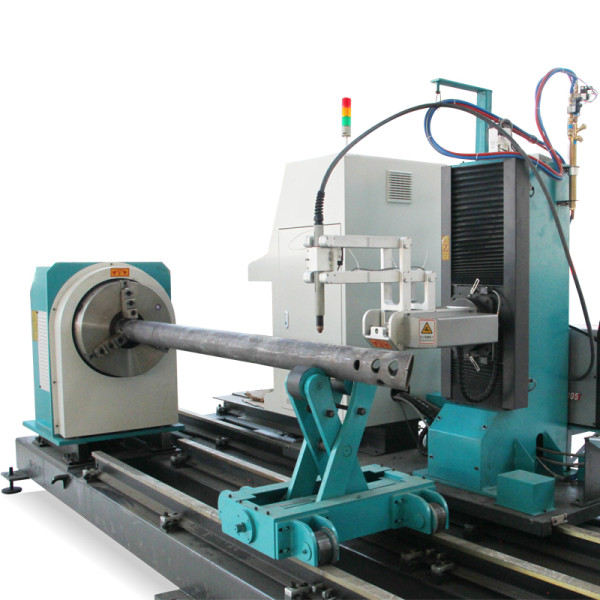

CNC Round Pipe Plasma Intersection Cutting Machine is special CNC equipment which is used for cutting metal pipe automatically.