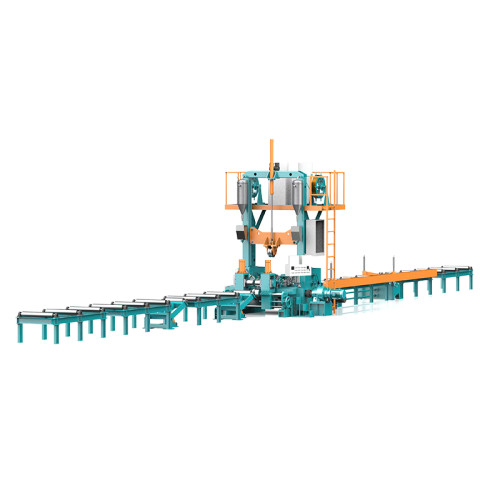

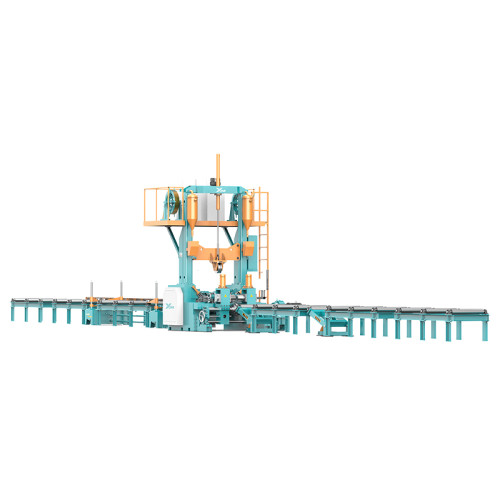

H-beam CNC Assembly Welding Straightening Machine

- Model

- PHJ0818

Item specifics

- Workpiece height

- 200-2000mm

- Web thickness

- 6-40mm

- Flange width

- 200-800 mm

- Flange thickness

- 8-60mm

- Controllable deformation of thickness

- The Max 40mm

- Workpiece length

- 4000-15000mm

- Conveying speed of the workpiece

- 6000mm/min

- Welding process

- Single arc single wire

Review

Description

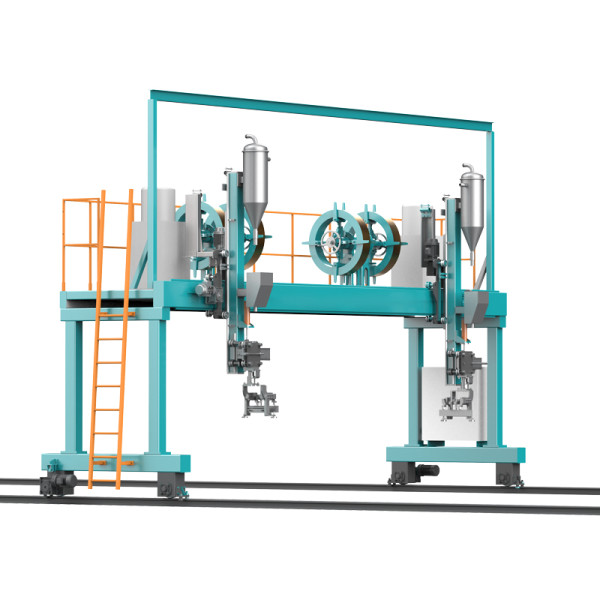

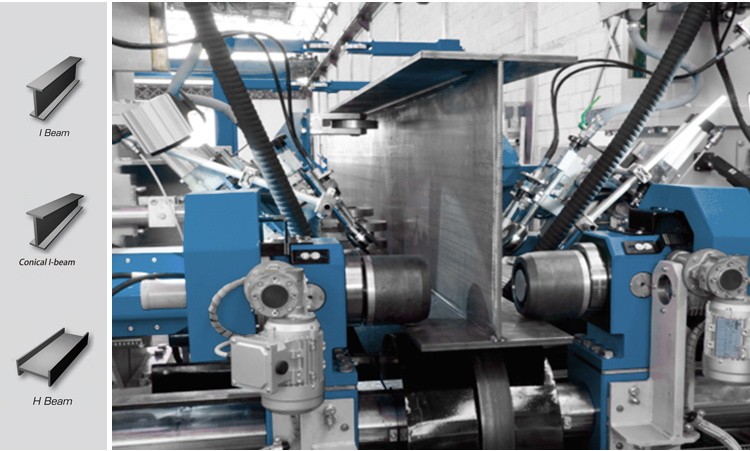

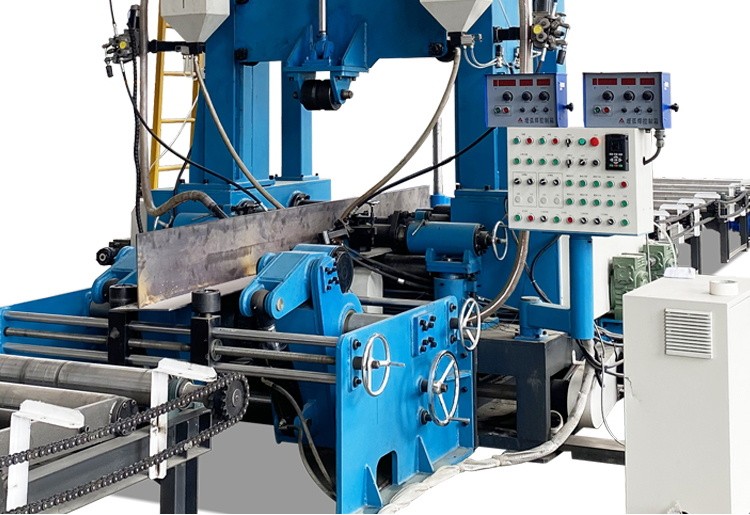

1.It is a special machine for assembling, welding and straightening of H beam/I beam/T beam.

2.It integrates the processes of assembly machine, gantry welding and straightening machine into one machine.

3.It significantly improves production efficiency ,reduces labour cost, saves installation space.

|

Item |

Technical Parameter |

||

|

Workpiece height |

200-2000mm |

||

Web thickness | 6-40mm | ||

Flange width | 200-800mm | ||

Flange thickness | 8-60mm | ||

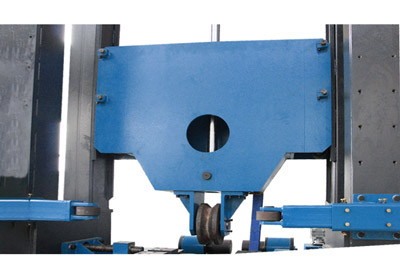

Controllable deformation of thickness | The Max 40mm | ||

Workpiece length | 4000-15000mm | ||

Conveying speed of workpiece | 6000mm/min | ||

|

Welding speed |

150-1500mm/min |

||

|

Welding process |

Single arc single wire, Double arc double wire, Single arc double wire. |

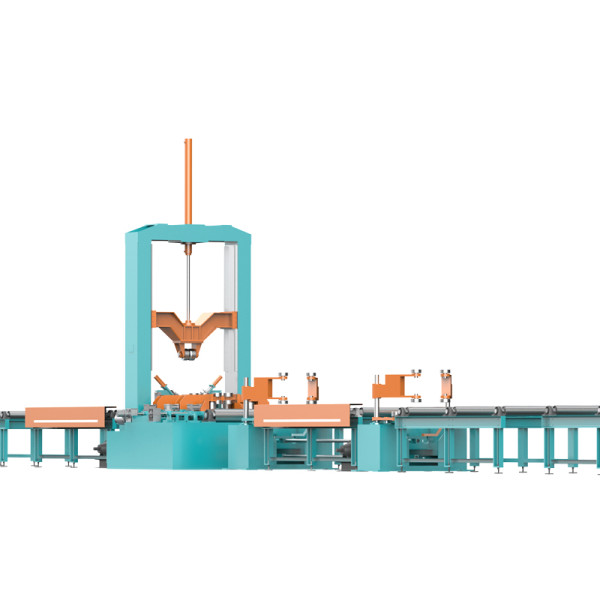

1. Assembly Parts

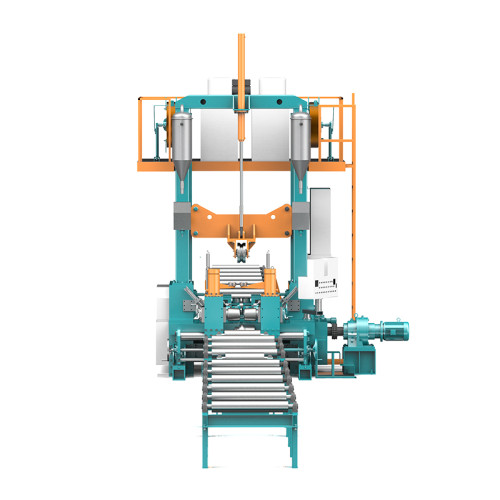

2.Hydraulic Assembly

3.Welding Parts

4.Bilateral Welding

5.Flange Straightening Part

6.Parametric Interface

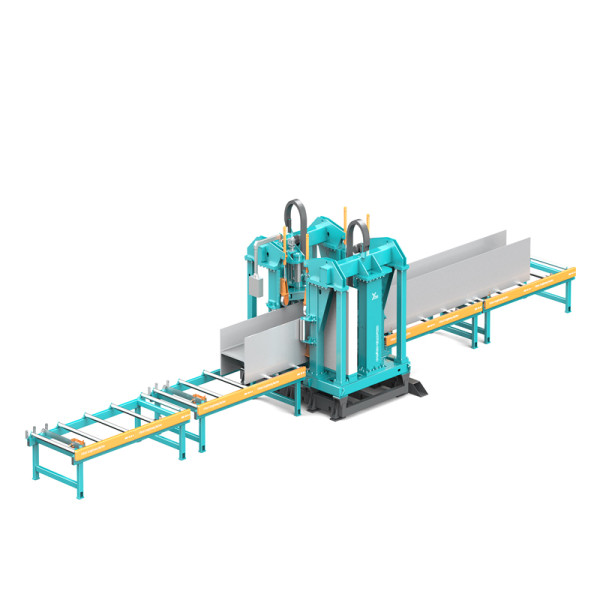

- Labor Saving:Traditional beam production line requires 5 workers, our 3 in 1 beam production line only needs 2 workers.- assembly, welding and straightening at the same time.

- Footprint Saving: The total length of traditional beam production line is about 90m, while 3 in 1 beam production line is about 30m lo, which saves two-thirds of loor area.- It can welding two seams once, while traditional only can welding one seam once.

- High Efficiency: Traditional beam production line needs to flip four times, 3 in 1 beam production line only needs to flip one time and the deformation is small.Saving 2/3 of the workspace.