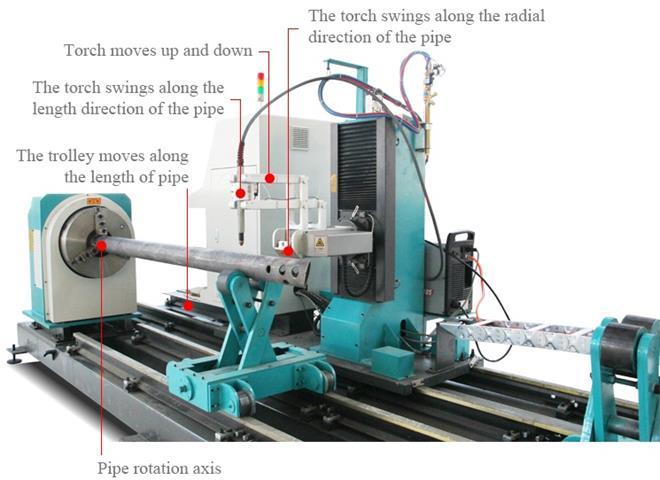

CNC Round Pipe Intersection Cutting Machine

- Model

- YM-XY5

Item specifics

- Round pipe diameters

- 60-630mm

- Effective cutting length

- 12000mm

- Cutting mode

- Flame/Plasma

- Plasma cutting thickness

- Pierce cutting: 1-25 mm Bevel cutting: 5-16mm

- Flame cutting thickness

- Vertical cutting 6~60mm Bevel cutting 6-40mm

- Plasma bevel angle

- Plasma cutting ±45°

- X Axis

- Torch move along pipe axial direction

- Y Axis

- Pipe rotation driving axis

- Z Axis

- Torch lifting

- A Axis

- Torch move along pipe radial direction

- B Axis

- Torch move along pipe axial direction

Review

Description

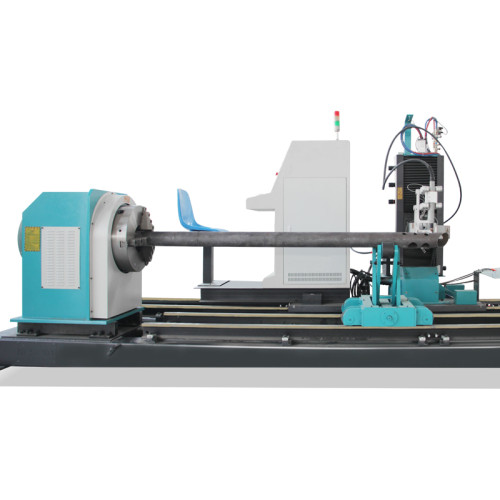

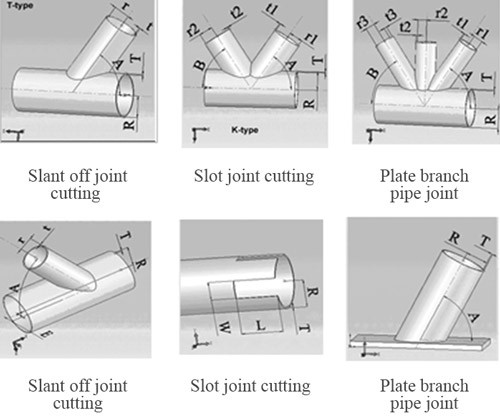

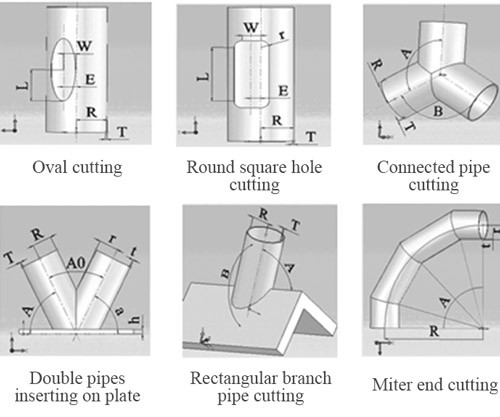

CNC Round Pipe Plasma Cutting Machine is special CNC equipment which is used for cutting metal pipe automatically. cnc plasma tube cutting machine can realize auto program and auto CNC nesting work for any complicated joint type of intertube, pipe, etc. and can cut any type welding bevel at one time.

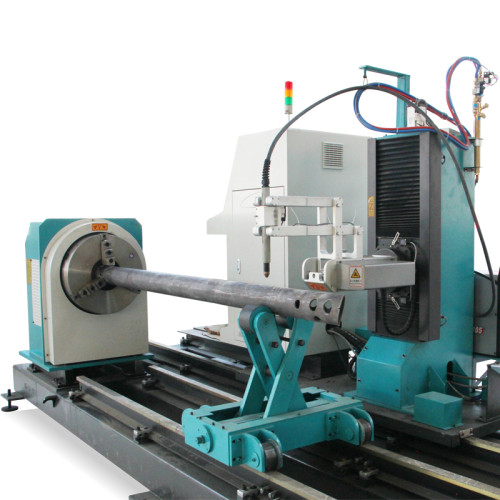

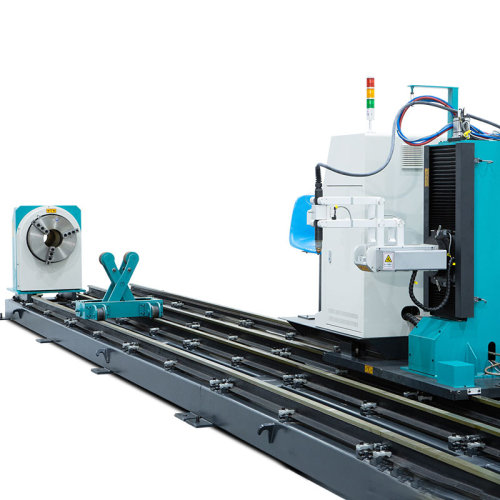

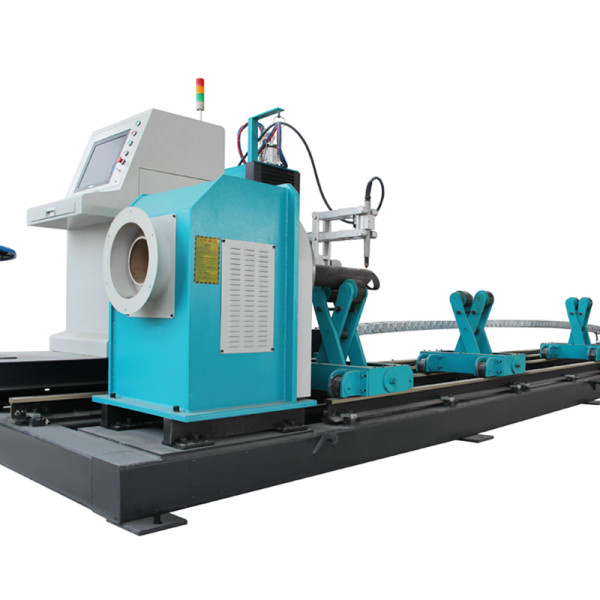

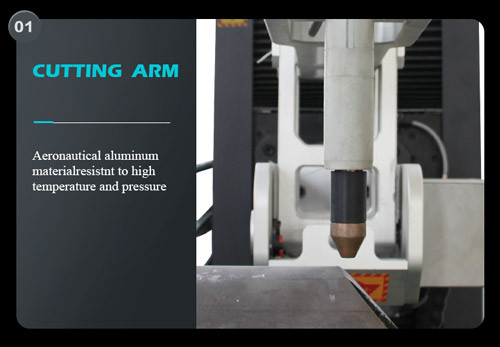

This machine is designed as a horizontal structure, mainly including base (square tube welding chassis), pipe rotating mechanism (three-jaw chuck and Y-axis rotating power device), steel pipe support bracket (4 groups of scissor shape brackets ), torch moving mechanism, torch lifting mechanism, torch deflection mechanism (the parallelogram structure material is manufactured by aeronautical aluminum CNC machining center), walking track (high-precision machining 24KG guide rail as the transmission component of trolley), electrical control system, etc.

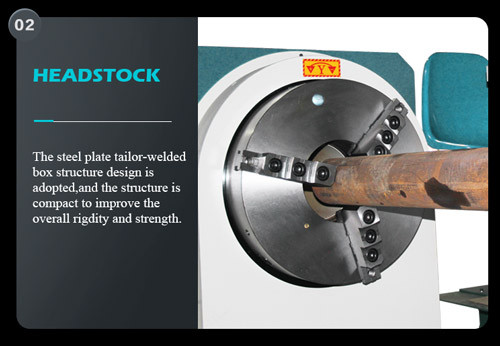

Y Axis:Pipe rotation driving axis | 360°free rotation, Japanese Panasonic 3000W servo motor,the driving system is driven by a precision gear box and gear pair, the speed is 0.01-8r/min, and the positioning accuracy is ±0.2° |

||

X Axis:Torch move along pipe axial direction | The max stroke is 12000mm,Japanese Panasonic 750W servo motor,the driving system is driven by precision gearbox, gear and rack, positioning accuracy ±0.2° |

||

Z Axis:Torch lifting (The axis does not participate in linkage) | Max stroke 335mm,Japanese Panasonic 750W servo motor,the driving system is driven by precision gear box and ball screw, positioning accuracy ±0.2° | ||

B Axis:Torch move along pipe axial direction | Swing±60°,Japanese Panasonic 400W servo motor,the driving system is driven by a precision gearbox, positioning accuracy ±0.2° |

||

A Axis:Torch move along pipe radial direction | Pendulum angle±55°,Japanese Panasonic 400W servo motor,the driving system is driven by precision gear box,positioning accuracy ±0.2° |

||

Processing size | Round pipe diameter | 60-630mm | |

Cutting length | Effective cutting length 12000mm | ||

|

Mainly used for thermal cutting of intersecting lines and ends of various piping systems.

|

|||

Applicable workpiece material: low carbon steel (copper nickel tube, stainless steel tube need to use plasma cut) | |||

Cutting Form | Cutting mode | Flame/Plasma | |

Plasma cutting thickness | Pierce cutting: 1-25 mm | Bevel cutting: 5-16mm | |

( It is depended by plasma power source ) | |||

Flame cutting thickness | Vertical cutting 6~60mm | Bevel cutting 6-40mm | |

|

Plasma bevel angle

|

Plasma cutting ±45°

|

||

Flame bevel angle | Flame hole cutting±55° | Flame end cutting±60° | |

Machine accuracy | Required workpiece ellipticity | ≤1% | |

Cutting speed | 10~2000mm/min | ||

Moving speed | 10~6000 mm/min | ||

Cutting length accuracy | ±1.5mm | ||

Standard for execution of cutting precision | ISO9013-2002 ,ISO8206-1991 and JB/T10045.4-1999JB | ||

|

Chuck type

|

Manual 3-jaw linkage self-centering

|

||

|

Manual chuck tightening device

|

1 set

|

||

Bracket | Quantity | 2 groups | |

Weight | Maximum loading weight | 5000Kg | |

Color | Machine color | Our company color or customized | |