Automatic Programming Nesting Software

- Model

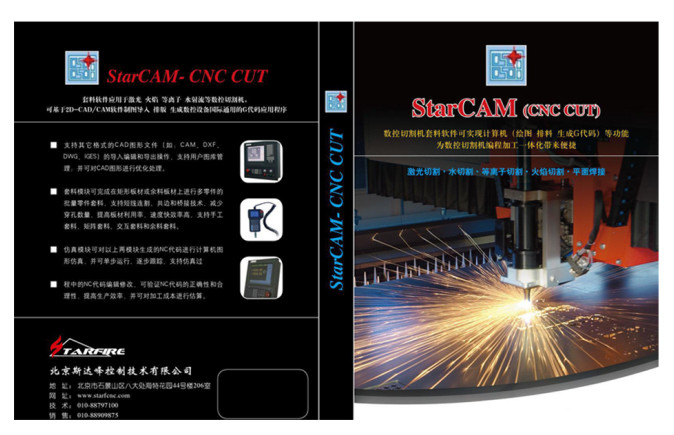

- STAR CAM cnc Cut

Review

Description

The development of STAR CAM cncCut is to meet the requirements of enterprises: it has many functions and is easy to operate. This software is suitable for various cutting methods, such as: water jet cutting, flame cutting, plasma cutting and laser cutting, etc., no need to load other software.

How CNC CUT works

Customers do not need to have basic knowledge, and can easily load DXF graphics into the software. Or use our integrated CAD-system STAR CAMCad to create graphics. Process data will be automatically generated through cncCUT graphics. The software will also provide the best processing path, and this processing path can be changed at any time as required. The graphics converted into CAM mode are directly generated, and there is no need to convert back and forth in different user interfaces. Only a few mouse clicks can get a complete nesting diagram. Then click again to generate the NC program!

We provide three nesting methods. The simplest way is to nest in the form of a grid. As its name says, all parts will be nested in a square grid, and then nested on the board. This nesting method is the simplest. Nesting in the form of a grid can only nest one type of parts in batches at the same time. The same is true for nesting. This nesting method is exclusively provided by our company. Its characteristic is that a single part can be compactly and optimally sleeved on the plate, thereby effectively improving the utilization rate of the plate. There is also a nesting method that is arranged in the correct shape, and multiple parts of different types can be nested at the same time. Therefore, the correct shape is often referred to as multiple parts nesting at the same time. All nesting methods have one thing in common, that is, the operation is fast and simple.

cnc CUT not only provides common functions, but also is equipped with unique functions such as common edge \ manual automatic interactive nesting \ drawing, which effectively improves nesting efficiency, metal sheet utilization, and saves processing time.