Steel structure H-beam welding and cutting equipment

- Share

- Issue Time

- Dec 20,2023

Summary

Steel structure H-beam welding and cutting equipment is a specialized production line designed to handle H-beam steel, integrating both welding and cutting functions for the manufacture and processing of H-beam materials in steel structures. This equipment is typically used in the production of building structures, bridges, towers, and various other steel constructions.

Steel structure H-beam welding and cutting equipment is a specialized production line designed to handle H-beam steel, integrating both welding and cutting functions for the manufacture and processing of H-beam materials in steel structures. This equipment is typically used in the production of building structures, bridges, towers, and various other steel constructions.

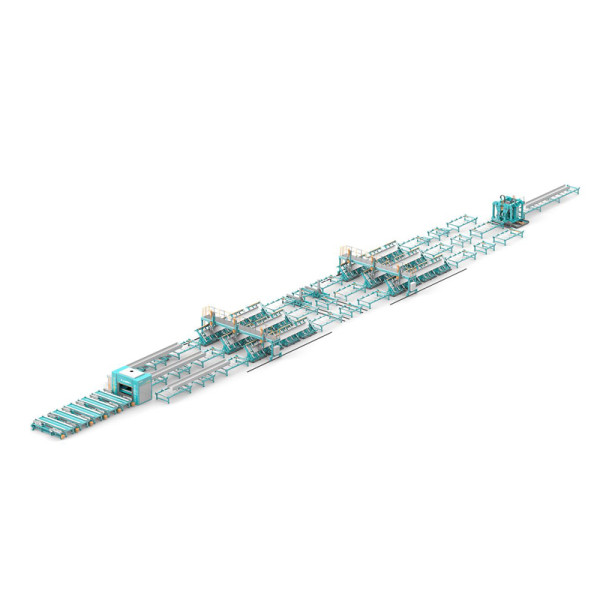

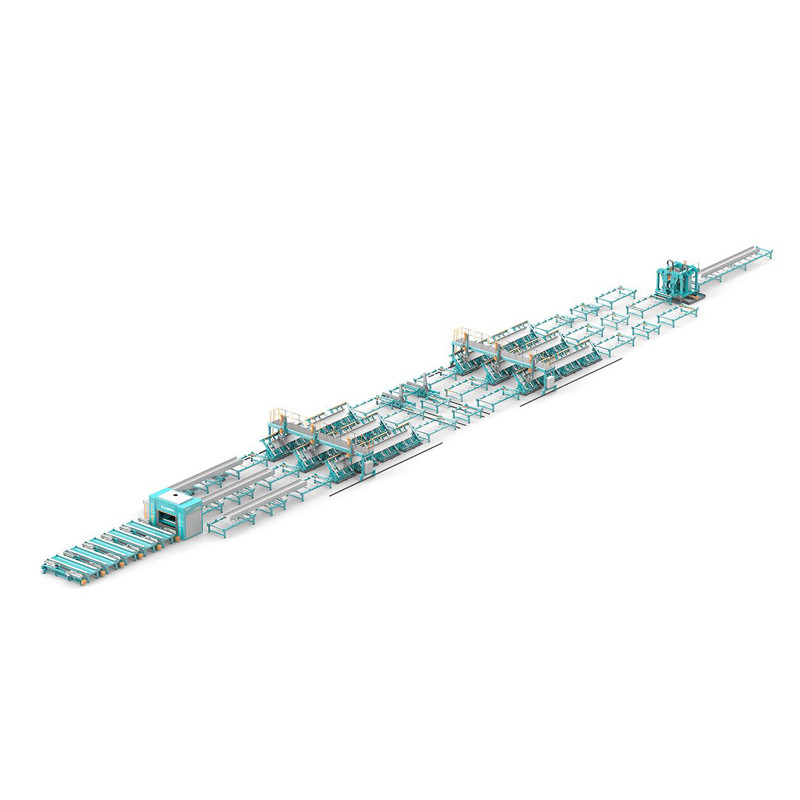

Multi-channel Horizontal H Beam Production Line H-beam can be made in single process.

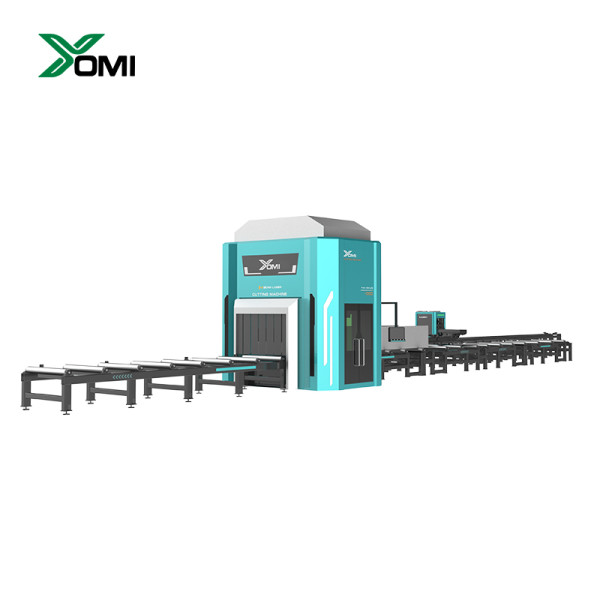

H beam Fiber Laser Cutting Machine Suitable for H-beam steel, U-beam steel, I-beam steel, slot steel and other profiles.

H-Beam Cutting Robort has been widely used in steel structure prefabricated buildings.

Here are some key features and introductions:

1.Automated production line: Steel structure H-beam welding and cutting equipment often includes automated steps such as feeding, positioning, welding, cutting, and stacking, which can significantly improve production efficiency.

2.Welding technology: These machines usually employ advanced welding technologies, such as submerged arc welding or gas-shielded welding, to ensure welding quality and efficiency.

3.Cutting methods: The cutting process can be accomplished through various methods like plasma cutting, flame cutting, or laser cutting, depending on different needs and budgets.

4.High precision and efficiency: Modern H-beam welding and cutting equipment are often equipped with high-precision control and automatic correction functions, ensuring the accuracy of the machining process.

5.Torque adjustment: Some equipment features an automatic torque adjustment function that adjusts the strength of welding and cutting according to the size and shape of the H-beam.

6.User-friendly interface: The user interface for operating these machines is usually intuitive and easy to use, facilitating the operator to set up programs and monitor the production process.

7.Maintenance and safety: The design of these machines also takes into account easy maintenance and operational safety, such as being equipped with protective devices to prevent accidental injuries.

Steel structure H-beam welding and cutting equipment is an indispensable part of structure manufacturing. They enhance the level of automation in production, ensure product quality, and maintain the continuity of production. With technological advancements, these machines.