Welding Positioner

- Model

- YM-10/30/50/100/300/600

Item specifics

- Rotating Speed

- 2-16r/min

- Tilt Range

- 0~90°

- Table Dimension

- 180mm

- Table Height

- 232mm

- Motor Power

- 20W

- Power Input

- 1PH 220V 50~60Hz

- Adapter chuck

- KC-65/KC-80

Review

Description

Description

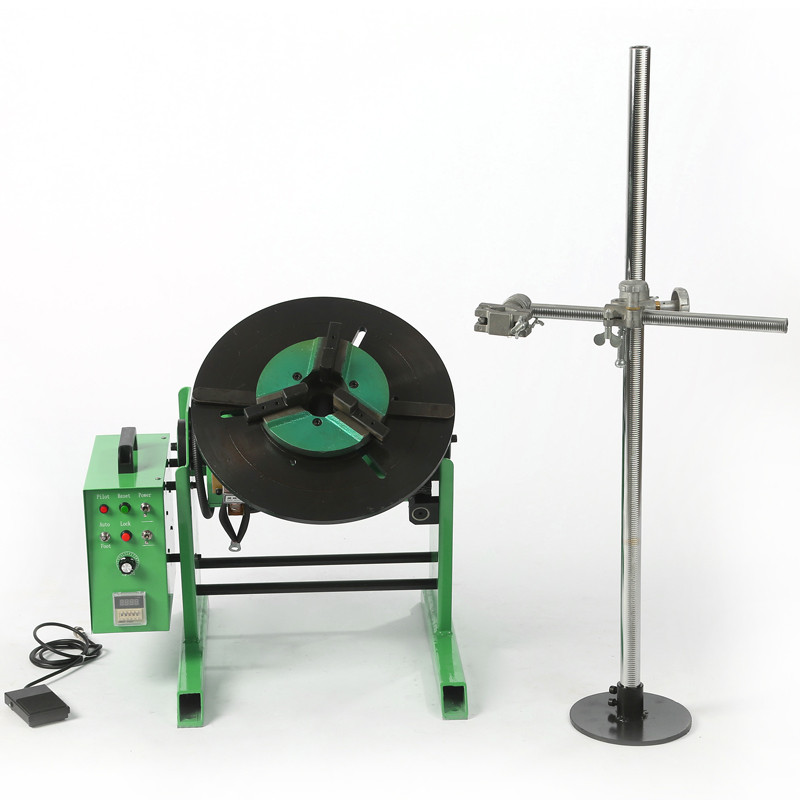

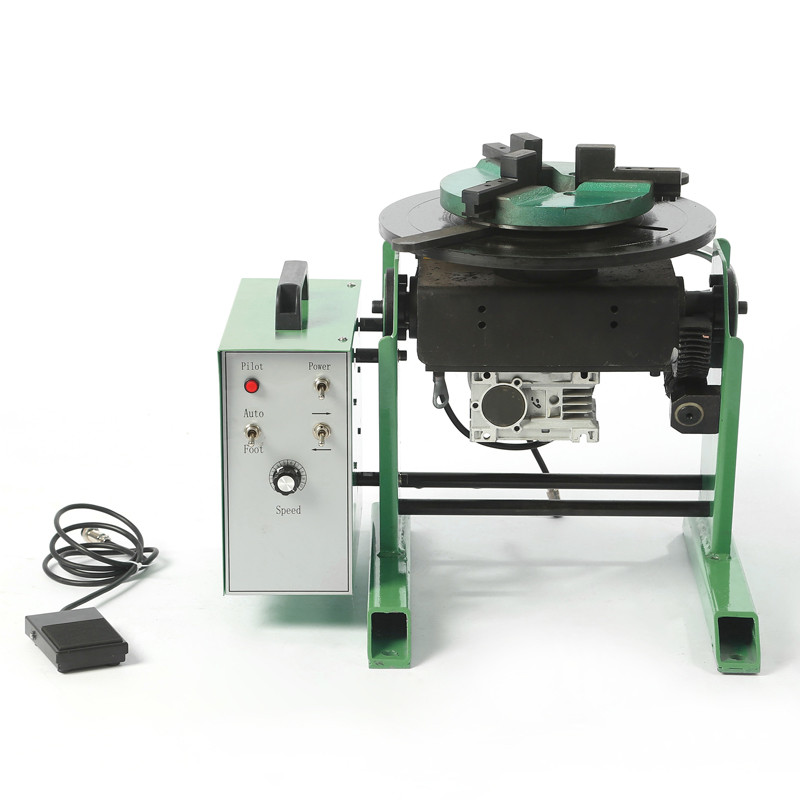

Welding Positioner

The welding positioner generally consists of a table, a slewing mechanism and a turning mechanism. The workpieces fixed on the table are brought to the required welding and assembly angle by the lifting, turning and turning of the table. The table rotates to variable frequency stepless speed regulation, which can obtain satisfactory welding speed.

FEATURES

600KG

300kg

170 Through Hole

100KG

50KG

30KG

VEDIO

Product Details

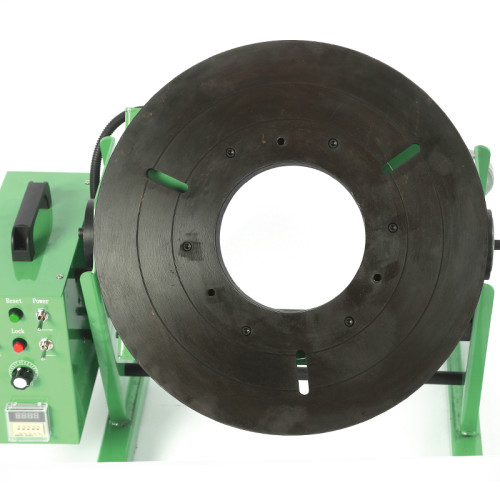

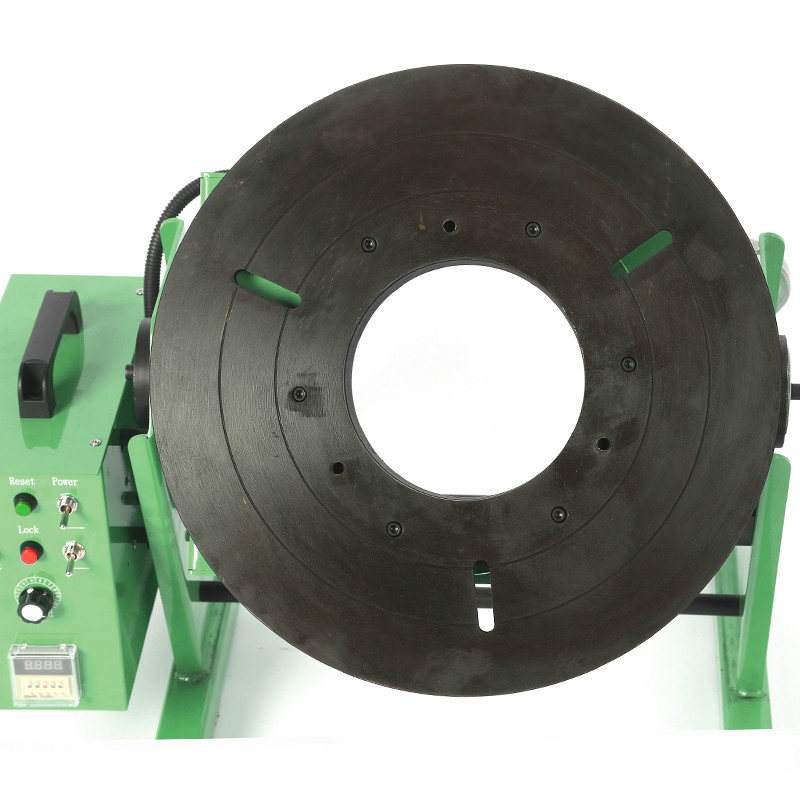

Rotation Structure

The rotation structure of positioner is driven by the DC motor, while stepless speed regulation can be achieved.

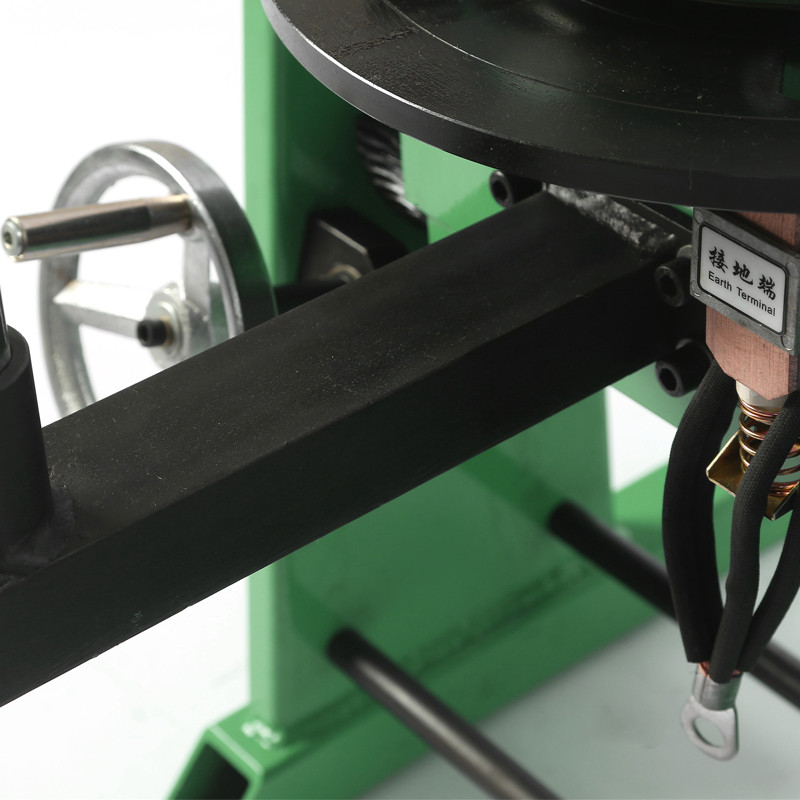

Worm and Gear

The turning structure of worm and gear has the function of self-lock, and the worktable can be turned steplessly between 0-90°.

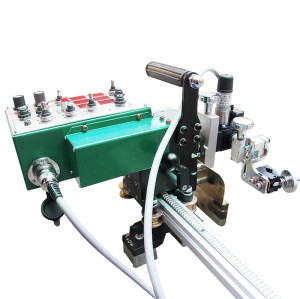

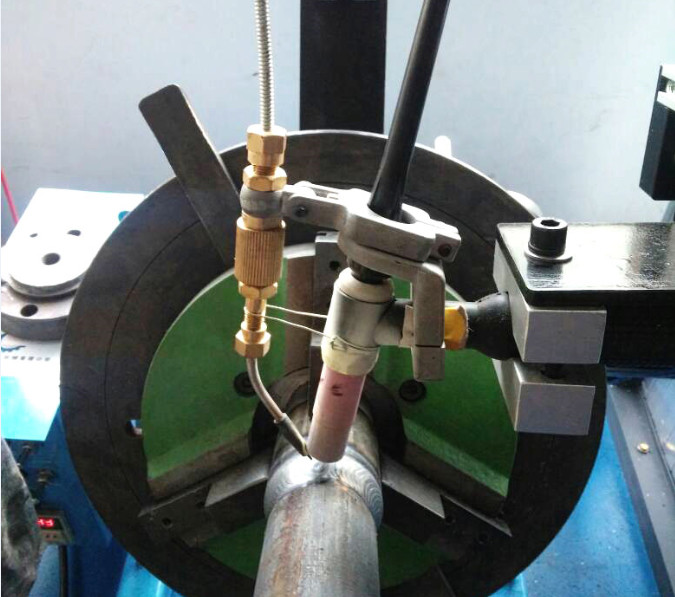

Welding Torch

The welding chuck and adjustable-welding gun support can be furnished to fix the position of the welding torch.

Air-powered tail tip

The air-powered tail tip can be furnished to achieve the function of self-holding to the workpieces.

Application

Welding Positioner

The welding positioner generally consists of a table, a slewing mechanism and a turning mechanism. The workpieces fixed on the table are brought to the required welding and assembly angle by the lifting, turning and turning of the table. The table rotates to variable frequency stepless speed regulation, which can obtain satisfactory welding speed.

Various Types

The series has various types of positioner such as roll type, head-to-tail rotary type, head-to-tail lifting type, head-to-tail tilting type and double-turn type. It can be combined with welding machine to form automatic welding machine. It can be used as a robot peripheral device to realize welding automation with the robot. At the same time, various special positioners can be designed and customized according to different types of workpieces and process requirements of users.