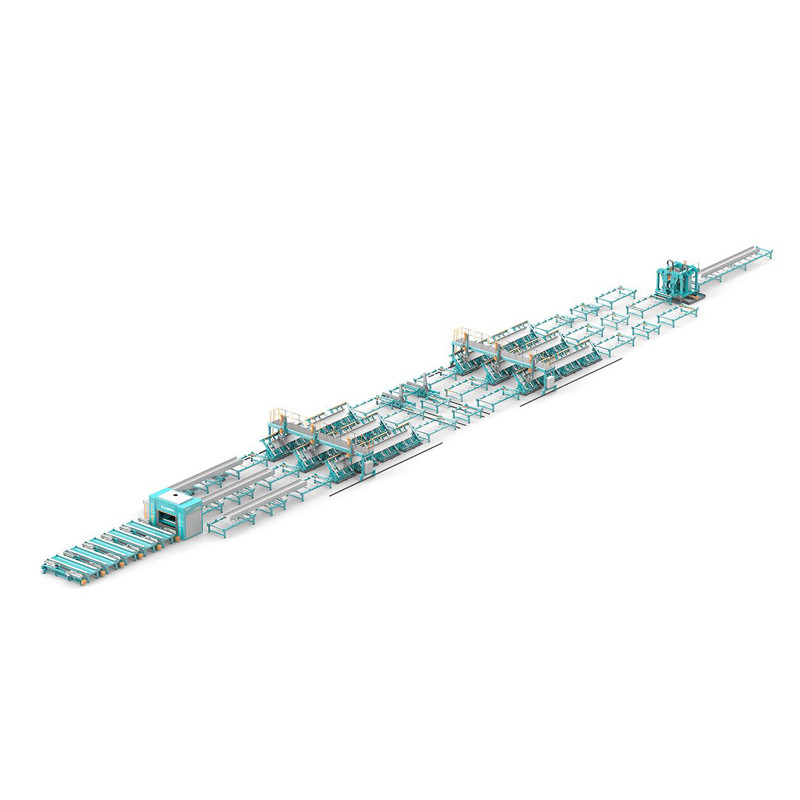

H beam production line

- Share

- Issue Time

- Apr 16,2024

Summary

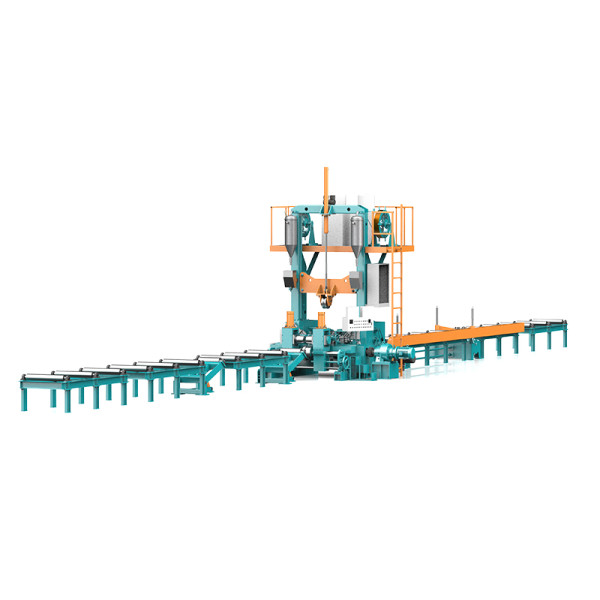

H beam production line is a series of machines organized systematically to produce H-shaped steel sections used in various structures like buildings, bridges, and other civil engineering projects. The H beam's shape gives it great strength and rigidity, making it a crucial element in modern construction.

H beam production line is a series of machines organized systematically to produce H-shaped steel sections used in various structures like buildings, bridges, and other civil engineering projects. The H beam's shape gives it great strength and rigidity, making it a crucial element in modern construction. A typical production line for H beams will include several key steps and corresponding machinery:

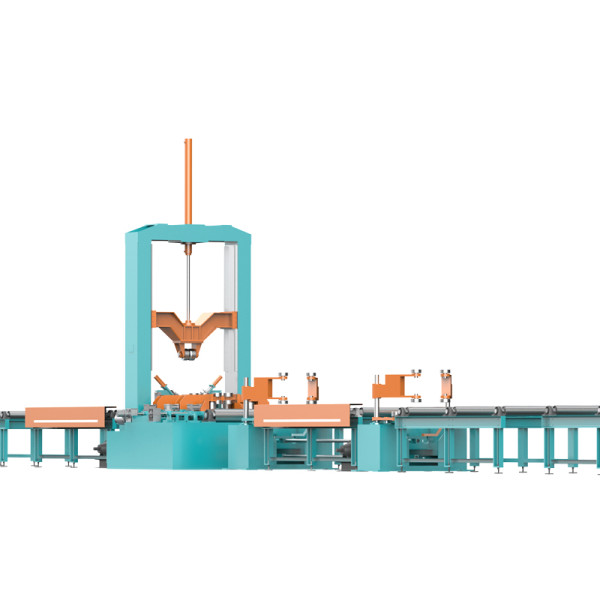

H Beam Assembly Machine is suitable for H -shaped steel with symmetrical and equivalent sections.

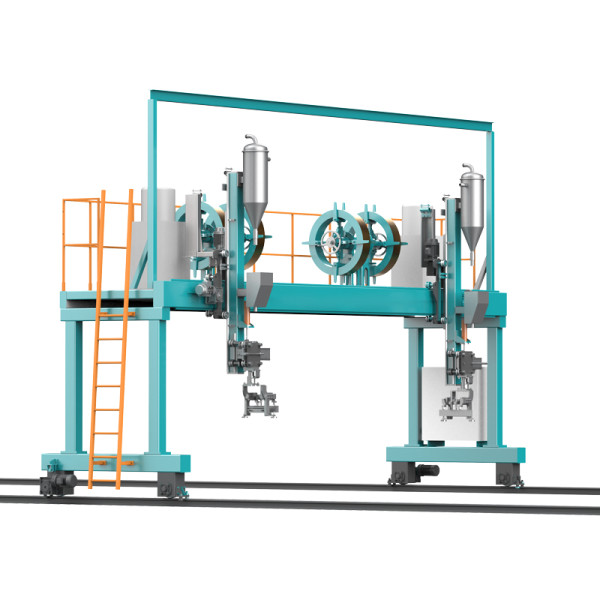

H beam gantry saw welding machine is special equipment used for H-beam welding.

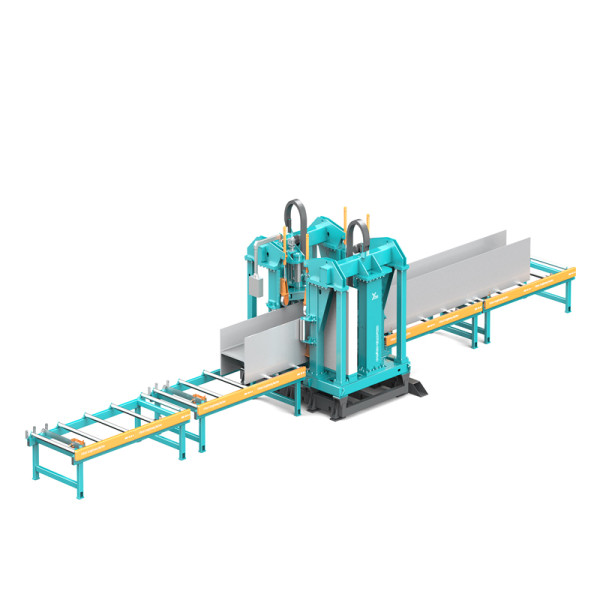

H Beam Horizontal Straightening Machine is to correct the flange plates on both sides at the same time.

1 Material Preparation Raw steel, the plates or coils, is prepared for processing. This may include uncoiling, leveling, and cutting-to-length.

2 Assembling: This step involves putting together the three parts of an H beam—the two flanges and the web. Automated assembly machines help to accurately position these components for welding.

3 Welding: Specialized welding machines, like the aforementioned 3 in 1 machine, are employed to join the flanges and the web.merged arc welding is typically used because it creates strong, high-quality welds.

4 Straightening: Post-weld heat can warp the steel, so straightening machines are used to return the beams to the correct shape.

5 Shot Blasting: To prepare the surface for finishing, shot blasting is used to clean and smooth the steel, removing any scale, rust.

6.Painting or Primer Coating**: Depending on end use of the beam, it may be painted or given a primer coating for corrosion protection.

7 Inspection and Quality Control: Throughout the production process, quality control is essential. This includes visual inspection, ultrasonic testing for the welds, and checking dimensions to ensure they meet specifications.

8.Cutting to Size and Drilling**: Finally, the beams are cut to the desired length, and any necessary holes are drilled for bolts and other fixtures.

Automation plays a significant role in modern H beam production lines, with computer-controlled systems ensuring precision and efficiency. By streamlining these processes, manufacturers can produce high-quality H beams at a faster rate and lower cost than ever before.