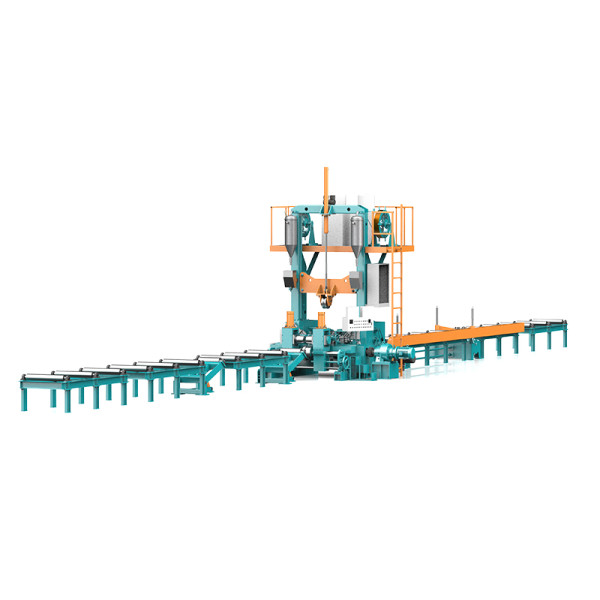

What is H-beam CNC Assembly Welding Straightening Machine

- Share

- Issue Time

- May 16,2024

Summary

n H-beam CNC Assembly Welding Straightening Machine, or simply referred to as an H-beam CNC Assembly Welding Straightener, is a type of CNC (Computer Numerical Control) machine that combines the functions of assembly, welding, and straightening in one single machine specifically designed for the production of H-beams.

This machine typically has the following key features and capabilities:

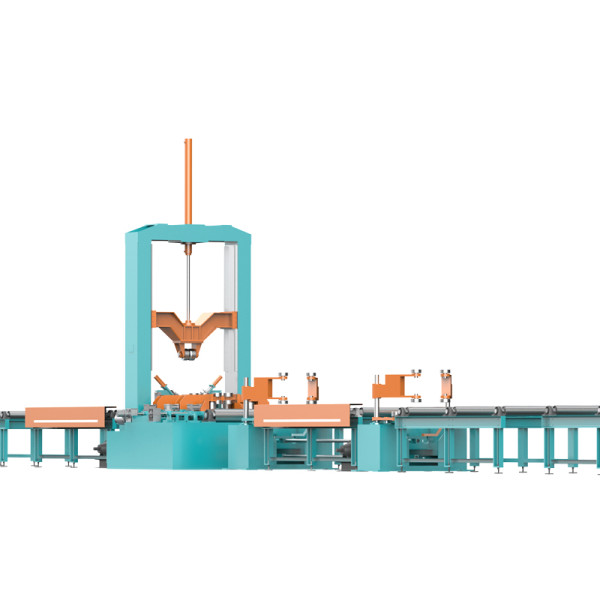

Assembly: The machine can automatically assemble the components of an H-beam, such as the web and flanges, into the desired shape and size.

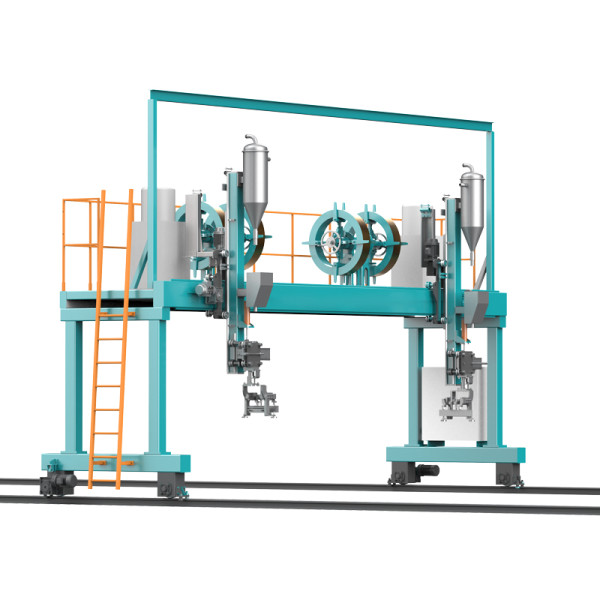

Welding: After the assembly is complete, the machine then performs the welding operation to fuse the components together, forming a solid H-beam structure.

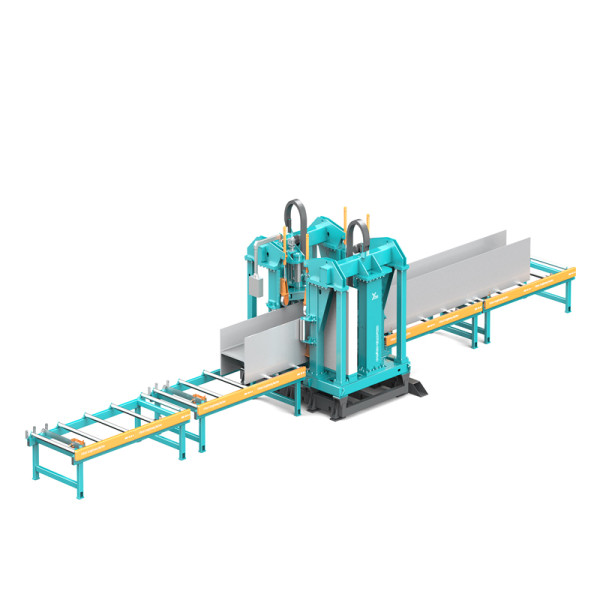

Straightening: The machine also has the ability to straighten the welded H-beam to ensure it meets the required dimensional accuracy and straightness specifications.

CNC Control: The entire process is controlled by a computer numerical control system, which allows for precise control of the assembly, welding, and straightening operations.

Efficiency: This machine greatly improves the production efficiency compared to traditional methods of manually assembling, welding, and straightening H-beams.

Automation: With the use of CNC technology, the machine can operate with minimal human intervention, reducing labor costs and improving consistency in the product quality.

Versatility: Depending on the model and configuration, the machine can be adapted to produce different sizes and types of H-beams.

Overall, an H-beam CNC Assembly Welding Straightening Machine is a highly efficient and versatile tool for the modern steel construction industry.