Advantages of the Assembly Welding and Straightening Integrated Machine

- Share

- Issue Time

- Jun 28,2024

Summary

The Assembly, Welding, and Straightening Integrated Machine boasts numerous advantages compared to traditional equipment.

The Assembly, Welding, and Straightening Integrated Machine boasts numerous advantages compared to traditional equipment. Firstly, its integrated design allows for simultaneous welding and straightening operations, significantly enhancing production efficiency. Secondly, the high degree of automation reduces the need for manual intervention and minimizes error rates. The machine's precision sensors and advanced control systems ensure superior welding and straightening accuracy, resulting in higher-quality products. Moreover, its flexibility and adaptability enable it to handle a wide range of workpiece sizes, shapes, and materials. Additionally, the machine contributes to environmental protection by reducing emissions during the welding process and saves energy through its efficient design. Finally, the integrated machine's compact size and high production output per unit area make it a cost-effective solution for manufacturers.

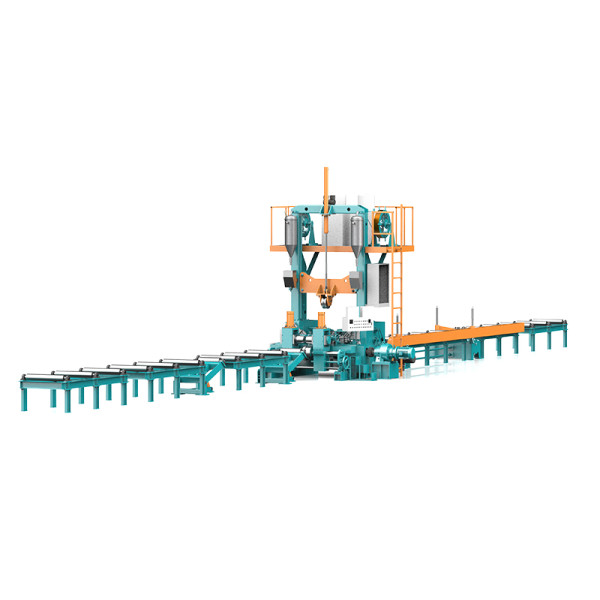

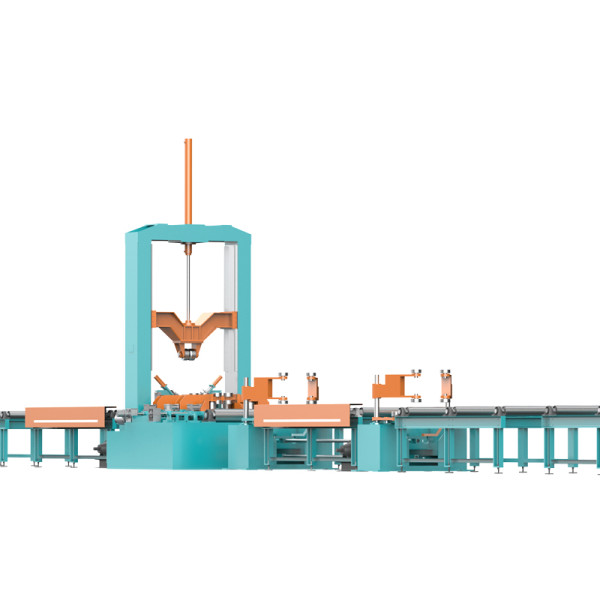

H Beam Assembly Machine is suitable for H -shaped steel with symmetrical and equivalent sections.

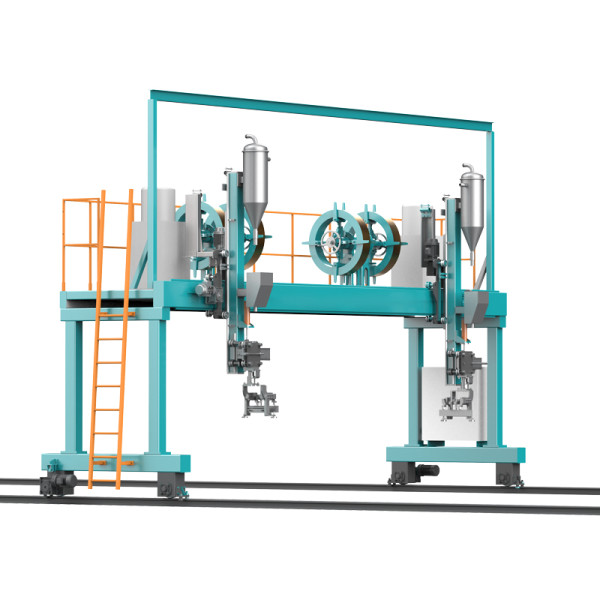

H beam gantry saw welding machine is special equipment used for H-beam welding.

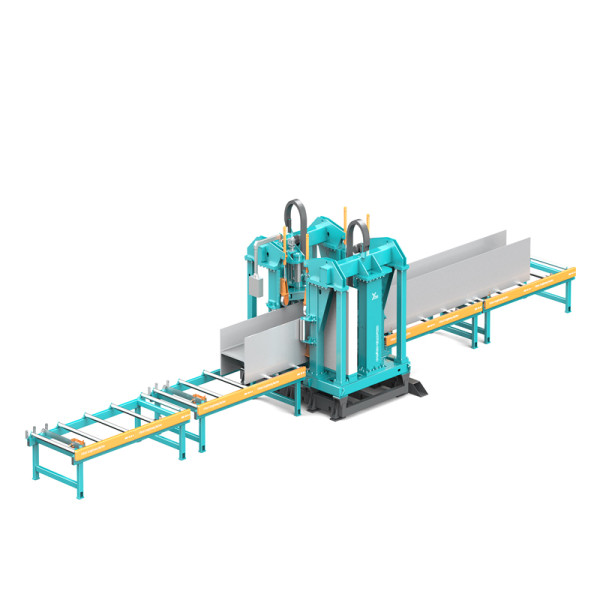

H Beam Horizontal Straightening Machine is to correct the flange plates on both sides at the same time.